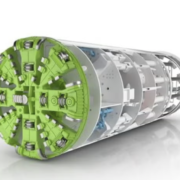

In accordance with the Sandoval’s claims, one of the advantages of its recently introduced DT923i jumbo rig, which is prepared for high-power face drilling in tunnels and caverns, is “Uncompromised accuracy and productivity.”

Installation of two electro-hydraulic booms, which are going to provide high levels of performance and reliability, is a new progress in Sandvik’s automated i-series of tunnelling jumbos. It is particularly suited for face drilling thanks to its computer-controlled auto-drilling functions and operator-controlled boom positioning. For simplifying the high-speed operation in this machines, the company’s new RD5 series of high-frequency rock drills and the latest information technology solutions, fast and automatic rod handling, and an ergonomically-designed cab and carrier, has been used.

Mattias Widenbrant, assistant project manager for tunnels at contractor Subterra stated: “The rig has an innovative new IT solution that streamlines and automates the drilling process. The new improved cabin creates a safer, cleaner working environment that is designed to reduce noise, keep dust out and optimize the viewing angle. All in all, it’s an innovative rig that enables us to work more flexibly and efficiently.”