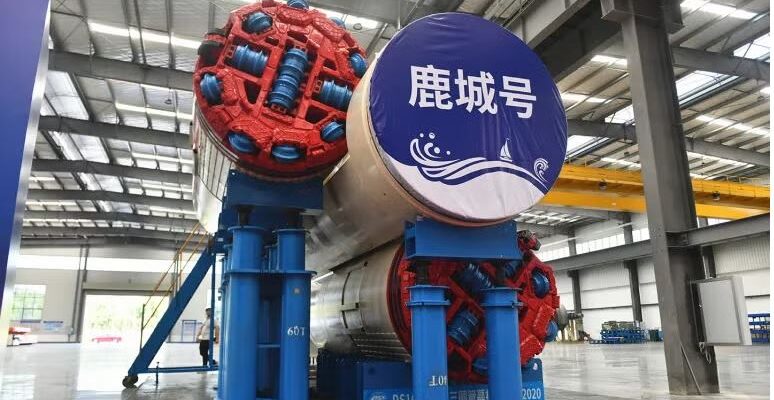

In order to advancing the Sanya Estuary Passage Project, CRCHI has produced a triple-circular pipe roof machine.

Providing a critical link between Sanya’s central business district and the Phoenix Coast Unit, this project implements in south China’s Hainan province.

Benefiting 12 pipe roof sections serving as both temporary support and permanent structure, construction of this undersea tunnel, which is going to have a cross-section of 18.4×18.4m, will be done.

Considering that the project features water-saturated strata, primarily traversing quartz sandstone, fault breccia, gravelly sand, and silty clay, with upper soft layers overlying extremely hard rock formations, features high compressive strength.

The innovative pilot-tube guided, multi-segment pipe jacking construction method for combined circular pipe roofing, is the method that CRCHI developed for overcoming these challenges.

The key customised technologies, including a multi-posture freely combinable machine, a multi-angle adaptive portal thrust system, a high-precision combined guidance and deviation correction system, and a special-shaped combined portal sealing system, are the features of this machine, named Lucheng.

According to CRCHI: “The successful implementation of this project will significantly improve construction efficiency and reduce operational risks. The equipment, which took four years to develop, provides breakthroughs in multiple cutting-edge technologies, filling critical gaps in the industry. Its successful development provides a pioneering CRCHI solution for worldwide projects with complex geological conditions and super-large tunnel face pipe roofing.”