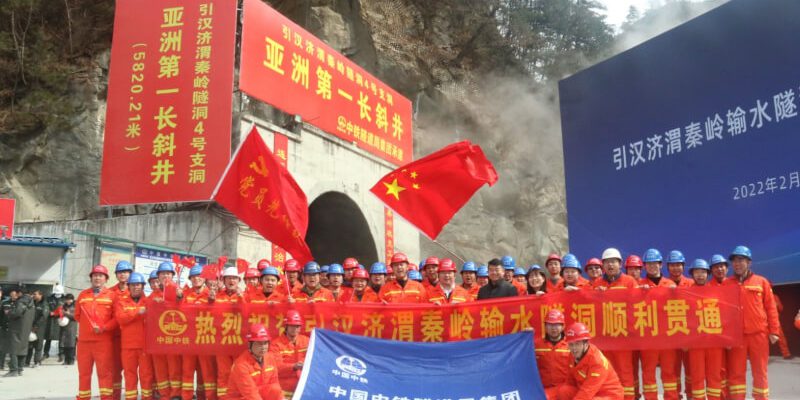

Digging 17.5km of the tunnel in what Robbins describes as some of the most difficult geology ever encountered, a Robbins main beam TBM with 8m diameter has completed this challenging drive in order to break through on China’s Yin Han Ji Wei project.

The location of this water diversion tunnel is the Qinling Mountains of Shaanxi Province, with up to 2,000m of cover.

Comprising of mainly quartzite and granite, the rock hardness of this ground was estimated to be between 107 and 309MPa (15,500 to 45,000psi) UCS, with high abrasively and maximum quartz content of 92.6%.

According to Robbins president Lok Home: “This was, in my opinion, the most challenging project ever completed by TBMs, and it proves TBMs are up to overcoming even the most difficult conditions. I have great respect for the CRTG crews and management, and I thank them for moving TBM technology to a new level.”

While during the tunneling process crews faced more than 14,000 rock bursts, some with energy as high as 4,080kJ, water ingress occurred 69 times during the drive, with some inflows extremely high – exceeding 20,000m3 of water in one day from a single point. In-tunnel ambient temperatures peaked at 40 deg C with 90% humidity.

The CRTG representative stated: “Robbins’ overall equipment performance was excellent from the beginning to the end of breakthrough, and during seven years of excavation. This is despite the super hard rock with high quartz content, strong rock bursts, and substantial water inrushes.”

Usage of the steel slats in conjunction with the McNally crown support system, as well as forecasting zones of stress using a micro-seismic monitoring system, were the considered solutions for rock bursting controlling. The function of the micro-seismic system is to record rock stresses in a borehole 20m ahead of the face and foretell the potential for rock bursting following comparative analysis with similar rockburst data from other projects, as well as from nearby sections of the tunnel in the Qinling Mountains.

Remarkably enhancing pumping capacity in the tunnel to 41,000m3 daily and benefiting systematic probing ahead of the TBM to detect water, as well as rock bursting, were done for water ingress controlling. When ingress exceeded 70 percent of the in-tunnel pumping capacity, crews then carried out grout injections.

The abrasive, hard rock was another challenge addressed by Robbins through the use of Extra Heavy Duty (XHD) 20in disc cutters that provided long cutter life and lower wear compared to standard 20in discs. The crew also optimized TBM operation with lower production rates when needed.

“Especially with such a huge challenge, a strong cutterhead is required to ensure production. The quality of Robbins’ cutterhead has been proven. The cutterhead can still work properly after the tunnel breakthrough,” said the CRTG representative.

As a part of two other sections of a tunnel with 82km length that is connecting the Hanjiang and Weihe Rivers in Shaanxi province, the completed tunnel, for owner Hanjiang-to-Weihe River Valley Water Diversion Project Construction Company, is going to secure a water supply for towns and agricultural areas in central China and also generate hydroelectricity.