We are a diverse and ambitious group of 30+ engineers from the University of Warwick, UK who qualified into the Finals of Elon Musk’s Competition as the top 3% worldwide (12 out of 400 applicants) so-called “Not-A-Boring Tunnelling Competition 2021” hosted by The Boring Company.

The aim of the competition: Selected finalists from around the world, “the Digging Dozen”, will each be racing their unique Tunnel Boring Machines (TBMs) in Nevada, this Summer. This is where our team will demonstrate our scalable, fast and cost efficient TBM by digging a 30-meter tunnel with a cross-sectional area of 0.2 square meters.

Our scaled-up TBM design is expected to be 80% faster than standard machines that typically dig one mile in 8-12 weeks. Moreover, we aim to dig at a cost that is 10X cheaper than traditional machines that typically would cost $100m – $1bn per mile to construct tunnels we use today. We followed “easy-to-assemble” approach. In addition, our machine is expected to operate at 1,500mm/min advancement rate and complete 30m tunnel in only a few hours.

How can Tunnels Benefit us?

- Unlimited Capacity – There is no practical limit to how many layers of tunnels that can be built! As the city grows, just add more levels.

- Minimal Land use – Tunnels minimize the use of valuable surface land.

- Minimal Surface Impact – Tunnel construction does not create any discernible surface noise or have an impact on surrounding land.

- Weatherproof – Weather has no impact on tunnels, unlike flying cars.

- Flexible usage – Tunnels can be used for pedestrians, cars, freight, utilities and have intracity as well as intercity connectivity.

- Future Expansion – Much easier to extend a tunnel network than a surface-based system

Sustainability in Mind

Tunnel Boring Machines (TBMs) are the future of innovation in tunnelling. Compared to traditional methods, such as Drill and Blast (that use explosives) TBMs provide a sustainable alternative to tunnelling.

1.Accurate Excavation

TBMs are very precise and remove soil very accurately. Therefore, in general they require relatively less amount of soil to be excavated compared to traditional tunnelling methods like Drill and Blast. This has a lower impact on the ground and its surrounding environment. Our TBM aims to dig tunnels from surface to surface which further reduces the amount of ground excavated as initial work to prepare for the launch is minimized.

2.Better Air Quality

Fewer emissions from equipment associated with tunnelling result in better air quality from a project. Our TBM is electrically powered and produces zero emissions during the process of making a tunnel.

3.Long-lasting design

The prototype is designed with smart inter-connections and reliable materials to ensure different safety factors in multiple environmental conditions. In terms of materials, where possible we have used materials such as Steel and Aluminum that can be recycled at end of life.

4.Reusability and Recyclability

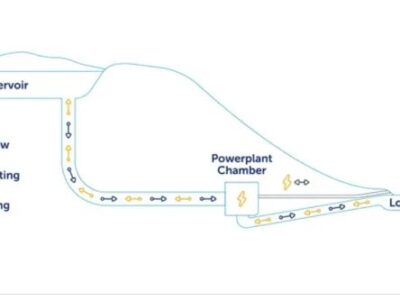

Our tunnelling method produces minimal wastage by recycling water by using a vortex pump which can be fed back in a closed loop system to reuse in different processes. The soil slurry being excavated from the ground can be removed and safely stored for use in the future which will also help us recover costs. An example of this would be The Boring Company using the slurry to build bricks.

5.Minimal Impact on Surrounding Land

TBM can operate without causing much disruption to the surrounding land. Tunnelling can normally cause a lot of disturbance to the land above making it very difficult to tunnel under urban areas. The machines overcome this barrier by causing minimal disturbance. For example, the Florence and Cecilia TBMs being used in the High Speed 2 project are able to dig tunnels under Chilterns in Buckinghamshire without troubling the residents living just above.

6.Sustainability in Activities

We will be using artificially created testbeds to ensure we don’t disrupt any land while testing. This will also allow us to be precise with energy requirements and eliminate any kind of wastage. We have tried to maximize the use of off-the-shelf parts which reduces the energy use in tooling and machining required for custom manufactured parts.

Our team of student and alumni engineers have worked tirelessly alongside exams, assignments and nine-to-five job commitments to bring this to fruition. We are eager to develop this machine and win the “Not-a-Boring Competition”.

We have a number of sponsors both announced and unannounced and the list is continuing to grow! We welcome collaborations and the support of companies looking to be involved or for people as excited as we are and want their name to be a part of the journey!

For more information, please visit here or email eashana@warwickboring.com.

We also have a GoFundMe page: click here.