On April 13, 2021, a significant landmark in the development of the Dianzhong Water Diversion Scheme, China’s biggest water diversion project, was achieved. TBM Yunling, the largest diameter gripper TBM in operation on foreign water diversion schemes, has successfully excavated 1,085.89m on the Xianglu Mountain tunnel, laying the groundwork for an early breakthrough of the tunnel and raising the possibility of the whole Project being completed on time.

The China Railway Tunnel Group Co., Ltd.-contracted Dali Section I Lot 3 Xianglu Mountain tunnel is 26.542km long and excavated using a mixture of drill+blast and gripper TBM, with the TBM driving a diameter of 20.82km. The construction of the main tunnel’s upstream section faces a number of challenges, including rapidly changing geology; a long-distance single direction heading with a continuously shallow depth; long-distance single direction heading ventilation issues; high ground stress, external water pressure, and seismic intensity; and an active groundwater environment with faults.

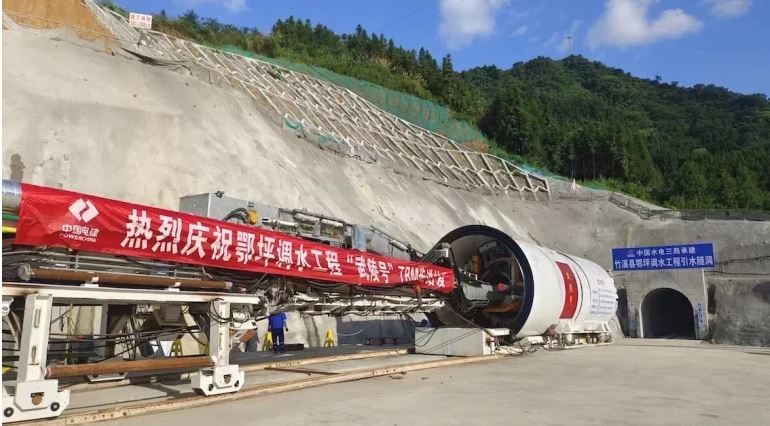

China Railway Engineering Equipment Group Co. built the TBM independently. Ltd. (CREG), which has an excavation depth of 9.83m, a total length of 235m, a total weight of approximately 2,050 tons, and a main drive capacity of 5600kW, both of which are uniquely built to deal with challenging geological environments.

The TBM has been outfitted with a number of special features, including automated seismic prediction, hazardous air control, and an emergency refuge chamber, all in an attempt to overcome possible geological problems during building, such as rockburst, massive deformations of soft rock, fault fracturing areas, and murky water in-rushes.

“This tunnel has a maximum buried depth of 1,450m and a maximum height difference of 494m. Muddy water gushing and large-deformation phenomena of soft rock may occur during the tunnelling process in the Xianglu Mountain tunnel. It passes through 13 large-scale fault zones. The excavation of the tunnel is like tunnelling in tofu, which means the geological conditions are very poor. Therefore, we have become increasingly more discriminating in regard to TBM performance,” stated Song Wu, the site design representative of Xianglu Mountain tunnel and engineer from Changjiang Institute of Survey, Planning, Design and Research department.

To resolve these challenges, the owner and builder have regularly invited experts to boost the progress of the drill and blast process and the full face TBM building.

“The Xianglu Mountain tunnel uses a gripper TBM with the highest diameter on world-class water diversion projects,” said project technical director Pengzu Xu. We can now excavate 25m a day, which is 3 to 5 times faster than the traditional drill and blast process. We can also overcome incredibly deep karst caves, which are uncommon during tunneling.

The construction details and work experience have also provided technological assistance for the Xianglu Mountain tunnel’s future single-direction headed tunneling. We are optimistic that we will meet the Xianglu Mountain tunnel construction speed target on time.”

The Dianzhong Water Diversion Project in China, which began in October 2018, is the most expensive and difficult-to-build scheme of its kind currently under operation, spanning six autonomous prefectures. (cities), Lijiang, Dali, Chuxiong, Kunming, Yuxi and Honghe, and involve 36 counties (districts), with a full length of 664km and a total estimated investment of 82.5 billion yuan. At present, the main works of the project have started, and the tunnel has been excavated for 187km.

When completed in October 2026, it is projected to effectively address the problems of unequal distribution of water supplies in Yunnan Province as well as regional drought in the center of Yunnan Province, benefiting a population of 11.12 million along the way.