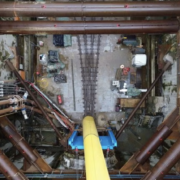

As a system for saving time and improving safety for mined tunnels, the lining erector machine (LEM) was revealed by Sydney Metro West as a world first in tunnel construction and is being used to line mined service tunnels.

The tunnels connect to the future stabling and maintenance facility at Clyde.

With the aim of lining the two 700m-long service tunnels with precast segments, rather than the cast-in-situ lining traditionally used for tunnels dug by roadheaders, the LEM has been custom-designed.

The location of producing these segments is the project’s Eastern Creek precast yard.

Considering that the usual way of lining the service tunnels would have included the slow and labour-intensive process of assembling large formwork sections, pumping concrete from the surface, and staging multiple pours, the project engineers adapted and refined the LEM inspiring by TBM technology and enabled it to complete an entire tunnel ring, built by piecing together four segments, in about one hour.

With 762m length and 6m diameter, the final service tunnel ‘s lining process took two months.

Installing 3,438 segments, the LEM is around 55m long, 6m wide and weighs 310 tonnes.

According to Sydney Metro: “The LEM approach is set to be a game-changer for the tunnelling industry, speeding up lining while delivering a higher-quality, watertight finish that matches the strength and finish of TBM-built tunnels, and making the job safer for tunnel workers.”