Being cast at the Polo Flat Segment Factory, the final segment has been cast for Snowy 2.0’s inclined pressure shaft and marks the completion of 7,101 world-first Force Activated Coupling System the (FACS) segments for the Australian pumped hydro storage project.

While the responsibility of building the project is up to Clough, part of the Future Generation JV, it said FACS was revolutionising tunnel construction, replacing traditional linings with a safer, high-pressure-tolerant system using innovative steel pin-socket couplers.

According to site engineer Bahador Dastorian,” Production of the final FACS segment was more than a milestone.It’s a revolution in hydropower construction and a testament to what’s possible when advanced engineering meets dedicated teamwork.”

It was an achievement that would inspire future projects worldwide, as Clough said.

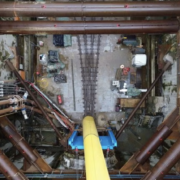

Production of the 25,000 segments that will be lined by the project’s newest TBM, will be the current aim of the Polo Flat factory , whereas the Herrenknecht TBM passed its Factory Acceptance Test in June.

Delivering the civil and electro-mechanical works for Snowy 2.0 is up to Future General JV, comprising Webuild and Clough anf the project is due to link two existing Snowy Scheme dams, Tantangara and Talbingo, through underground tunnels to depths of up to 1km and an underground power station with pumping capabilities.

Snowy 2.0 will provide an additional 2,200 megawatts of dispatchable, on-demand generating capacity and approximately 350,000MW hours of large-scale storage to the National Electricity Market.