The Tunnelling Association of Canada has the published the full list of the 2024 TAC Achievement Award recipients.

This year’s awards, presented last month, are:

- Lifetime Achievement Award – Serge Moalli

- Young Tunneller of the Year Award – Ashley Galagusz

- Tunneller of the Year Award – Tim Cleary

- Canadian Innovation Initiative Award – Innovative approach to install precast segmental lining in lieu of cast-in-place in starter tunnels

- Canadian Project of the Year Award (up to C$300m) – Second Narrows Water Supply Tunnel

- Canadian Project of the Year Award (over C$300m) – Réseau Express Métropolitain

- Photo of the Year Award – Tunnel Glow (260m Radial Curve) Eglinton Crosstown West Extension

- Dan Eisenstein Memorial Scholarship – Katherine Westerlund

- TAC Undergraduate Scholarship – Ethan Spieker

Lifetime Achievement Award – Serge Moalli

Serge Moalli’s long civil engineering career is a testament to dedication, innovation and leadership. Graduating with a degree in Civil Engineering from Ecole Polytechnic de Montreal in 1977, Moalli has spent the past 47 years immersed in the tunnel and underground industry.

He began his career working on deep interceptor sewer projects in Montreal in the 1980s, followed by soft ground tunnels in the US in the 1990s.

He has risen from office cost and field engineer, project engineer and project manager to managing EBC’s tunnelling and underground group.

During his career, Moalli has been involved in the construction of around 50km of tunnels, employing various methodologies and innovative techniques across North America. A priority has been building a strong talented team through collaboration and mentorship.

Mollai is a long-standing member of TAC and Society of Mining, Metallurgy and Exploration.

Young Tunneller of the Year – Ashley Galagusz

Ashley Galagusz has been involved in some of the most challenging and impactful undergound projects across Canada for a decade.

After graduating from McGill University in Montreal, she became a tunnel engineer in training at MMM Group in Ontario. In 2016 she jointed Black and Veatch where she took on a pivotal role in the integrated pumping station project for Toronto, leading the design of intricate micro tunnels, rock tunnels and shafts.

On the Darlington nuclear project she has overseen the design of a new intake and outfall tunnel beneath Lake Ontario.

Her current role is tunnelling practice lead for northern California and the Pacific north-west where she’s responsible for project execution and for staff and business development. She shares her experience in several author and co-authored technical papers and does volunteer work with Women in Science and Engineering and the underground association’s women in tunnelling group.

Tunneller of the Year –Tim Cleary

For decades Tim Cleary has been at the helm of some of the most ambitious tunnelling projects in North America. As general manager for tunnels at McNally International, has played a pivotal role since the inception of the company.

His portfolio of projects reads like a history of modern tunnelling, including the 14th Avenue sewer in 1993; Sheppard Subway, Toronto 1999; 9th Line sewer in 2000; 16th Ave sewer in 2004; Edmonton South LRT 2007; York Spadina Extension, Toronto 2013; Burnaby Mountain tunnel 2022; and the West Vaughan Sewer, Ontario this year.

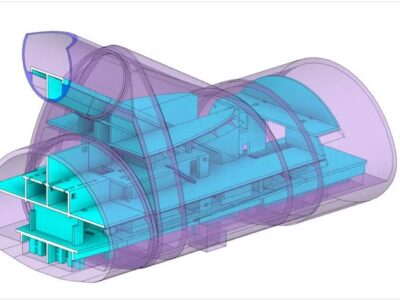

Canadian Innovation Initiative Award – Innovative approach to install precast segmental lining in lieu of cast-in-place in starter tunnels

Coxwell bypass project in Toronto will capture store and transport combined sewer overflows to the Ashbridges Bay treatment plant. Building the 10.5km bored tunnel Jay Dee Canada, lead partner of North Tunnel Constructors, required a solution to overcome the challenges of casting the final lining of the starter and tail tunnel excavations.

A pioneering machine designed and built in collaboration with Everest, proved an efficient and cost-effective solution. The ring machine erector assembles, transports and installs pre-cast tunnel segments one ring at a time with a rigid rotating platform, known as the Spider.

Segments are assembled horizontally into a full ring at the base of the launch shaft and then the assembled the ring is pivoted forward, transported along the tunnel on rails and positioned with precision, thanks to six degrees of freedom of adjustments.

The machine’s advanced controls allow for meticulous adjustments in roll, pitch and lateral positioning. This ensures the segment ring aligns with the existing liner which is critical for maintaining the tunnel’s geometry and integrity.

Using this cable and pulley system, the Spider pulls the ring tight against the liner using hydraulic cylinders to maintain the necessary gasket compression. Once in place the segment rings are supported by timber and steel blocks and secured with steel straps. The completed liner is then backfilled with cellular concrete.

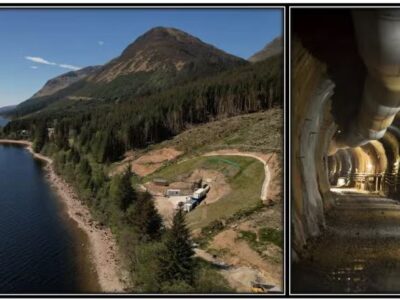

Canadian Project of the Year up to C$300m – Second Narrows Water Supply Tunnel

Second Narrows water supply tunnel is set to replace three of the region’s critical water mains in metro Vancouver. The 1.1km tunnel connects North Vancouver to Burnaby, crossing varied and complex ground conditions from gravelly soil to weak rock, all while designed to withstand a 1 in 10,000 years seismic event.

The tunnel is not only one of the deepest and highest pressure soft ground tunnels in Canada, it is also the largest water supply tunnel in the lower Mainland. Challenges included extreme ground water pressure and seismic demands, requiring innovating design and precise execution.

The north shaft construction features a support of excavation system comprising 22 unreinforced concrete slurry wall panels, each extending 80m into the earth and excavated by combination of grab and hydro mill. By incorporating separation between the initial excavation and the final lining, significant reductions in localised stress concentrations and seismic demands were realised, resulting in improved constructability and a substantial reduction in steel reinforced concrete and cost.

On the south shaft, synthetic reinforced shotcrete and steel ribs and lattice girders provided the initial ground support. The north and south valve chambers were designed to transition the three water mains from the shafts to existing buried pipes.

Launching the TBM from the north shaft required highly specialised planning. The project team in collaboration with the owner developed a TBM launch lock, the first of its kind for a 6.6m machine in such high pressures. This system allowed the TBM to be fully pressurised before breaking out of the shaft. The Herrenknecht mixed shield TBM was designed to handle pressures up to 7 bar.

Canadian Project of the Year over C$300m – Réseau Express Métropolitain

The new automated Réseau Express Métropolitain (REM) light rail network is the largest public transit initiative in Quebec for more than 50 years. CCH JV was awarded the design build contract and the construction contract is being undertaken by NouvLr consortium, comprising Atkins, Dragados, Aecon, Pomerleau and EBC.

The project includes two remarkable underground structures – the existing Mont Royal tunnel and the new airport tunnel which stretches 3km beneath active airport runways.

The 5km-long Mont Royal tunnel is transformed from a commuter rail to a high efficiency light rail system with two new underground stations. Reconstruction of the old tunnel was a significant challenge, especially the need to rehabilitate a 540m portion in the south where undetonated explosives from the original construction and required the use of remote-controlled drilling equipment.

In the heart of the University of Montreal campus the Edouard-Montpetit station was excavated by drill and blast and, at 70m underground, is one of the deepest metro stations in North America.

The new airport tunnel, excavated by an EPB TBM, connects to the airport station, passing beneath runways and taxi ways.

The first trains began running on the news line in 2002; the full network will be in operation by 2027.

Tags: # Tunnelling Association of Canada # Achievement Award Recipients # Events # Canada # Tunneling