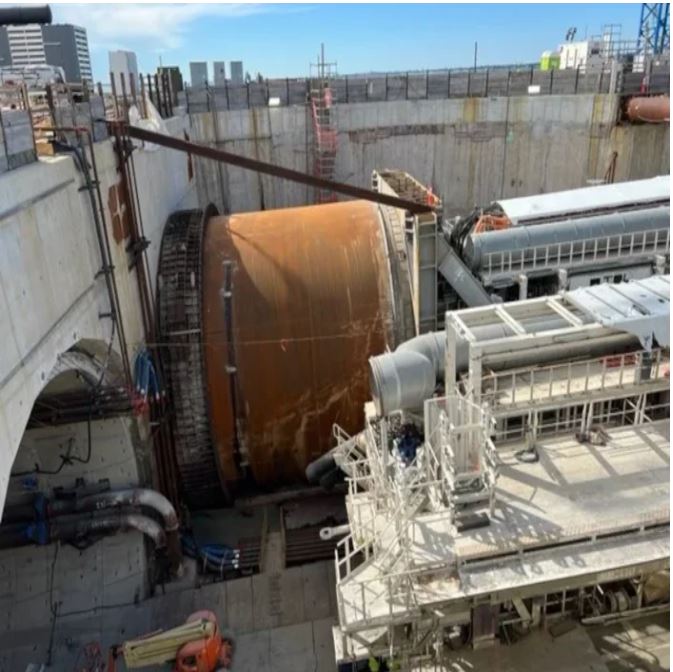

While undergoing the tunneling process the second bore of the Hampton Road-Bridge Tunnel Expansion project (HRBT) in Virginia, excavating back towards South Island is advancing by TBM Mary after breaking through at the North Island reception pit, completing the first bore, and Virginia’s first bored road tunnel, in April.

In order to ensuring efficient effective operation on the return trip to South Island, TBM Mary underwent extensive maintenance following completing the first 2.41km tunnel.

According to HRBT Expansion project director Ryan Banas: “The TBM cutting tools were inspected and replaced as necessary, all parts cleaned, and proper operation verified, and a detailed commissioning and testing procedure ensured the operation of the TBM and the safety of the crew operating it.”

With aim of rotating the variable density TBM for the return journey, Nitrogen skates were used.

Considering that the spent time duration for digging the first tunnel was 51 weeks, Banas expected that the experience gained would enable the second tunnel to be completed more quickly.

As Banas told T&TI: “Many lessons were learned during the first bore, but the most significant is how to operate the TBM slurry treatment plant, and all the logistics around both, such as muck disposal, segment delivery, consumable supply, operation of bicomponent plant, operation of water treatment plant, in harmony to maximise production and minimise downtime and quality issues.”

“Furthermore, the team has nearly one year of experience operating the TBM under their belt. This boots-on-the-ground experience allows them to appreciate the tendencies of the machine and how it will likely behave in specific ground conditions,” added Banas.

Due to facing the geology of the alignment that mainly comprises alluvial fine-grained and coarse-grained sands with some areas of plastic and organic soils, the ground conditions for the second tunnel are considered soft by geotechnical standards. Also, underneath the two islands are artificial fill and zones of ground improvement.

“The challenge of boring subaqueous tunnels in soft soils was added to by the sheer weight and size of the TBM. At 4,700 US tons with a 46ft (14m) diameter, TBM Mary is well matched for the task of excavating Virginia’s first ever bored tunnel for vehicular traffic. Coupled with an offshore marine environment for launch and receiving pits, the necessity for just-in-time logistics, and the weather restrictions faced by supporting cranes and barges, there are many challenges associated with expanding the HRBT,” Banas said.

He also added: “The challenges of the two tunnels were very similar, but the second tunnel’s supply of slurry and segments required even greater co-ordination as both items would continue to be supplied from South Island.This means slurry and segments will travel up to three miles underground prior to being incorporated into the tunnel just prior to the TBM’s arrival on South Island.”

Being separated from the road, the interior of each tunnel includes an emergency egress corridor.

As the largest highway construction project in Virginia’s history, the HRBT’s value is US$3.9bn, whereas it aims to reduce congestion along a 16km corridor on the I-64 through the addition of twin, two-lane bored tunnels beneath the harbour from Hampton to Norfolk and the widening of four-lane segments.

The responsibility of building this project is up to Hampton Roads Connector Partners (HRCP), a consortium of Dragados USA, Vinci, Flatiron Constructors, and Dodin Campenon Bernard.