In order to completing the tunnel for the Guangzhou-Zhuhai-Macao high-speed railway section of the Guangzhou Baiyun Airport T3 transportation hub, CREG Baiyun Pioneer, which is a shield TBM manufactured by the China Railway Group, made its final breakthrough.

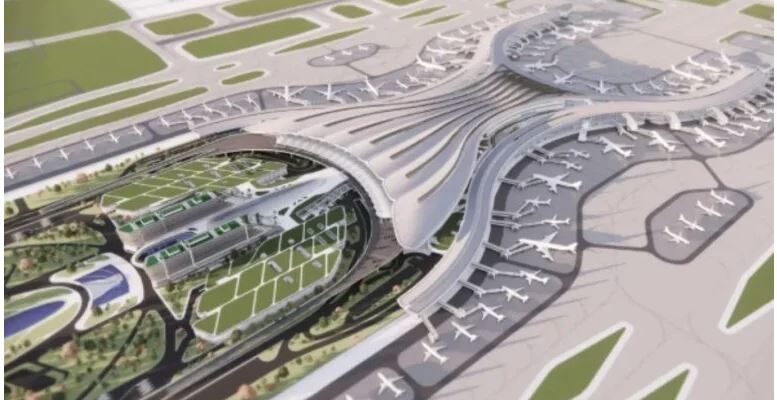

The Baiyun Airport T3 hub station, the Guangzhou-Heyuan high-speed railway (Guangcong Intercity), the Guangzhou-Zhuhai- Macao high-speed railway section tunnel, as well as the east and west section tunnels of the Fangcun to Baiyun Airport Intercity, are the contents of Baiyun Airport T3 transportation hub railway reserve project.

Involving one station and four tunnels, total length of these sections is 5.5km.

Considering the 48.94%, karst cave detection rate and the karst line rate of 13.54%, the 1.476km-long Guangzhou-Zhuhai-Macao high-speed railway section tunnel posed significant construction challenges, whereas 98% of the shield tunneling route was within the airport’s operational flight zone, with the tunnel passing directly underneath the airport runway, and the vertical distance from the tunnel segment to the ground surface of the flight zone was only about 11.246m.

Additionally, the shield tunneling phase required strict control over the total cumulative settlement, which was not to exceed 30mm, with uplift limited to 10mm. Differential settlement could not exceed 1%, and segment joint misalignment had a 5mm tolerance.

Also due to insufficient launch shaft length and ultra-shallow shield tunneling, the height restrictions at the airport and limited working space created challenges.

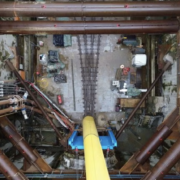

The reason that China Railway (Guangzhou) Investment & Development co-ordinated and integrated resources, and collaborated with the China Railway Tunnel Group, which was responsible for the shield tunneling work, was toTo ensure the project proceeded smoothly. As the largest diameter shield machine currently used in Guangzhou metro construction, they deployed the 14.31m-diameter CREG Baiyun Pioneer shield machine.

With 115m length, almost 2,500 tons weight, this TBM is equipped with online tool monitoring, advanced geological forecasting functions, a dual-channel muck removal system (screw machine + direct discharge pipe), as well as cutting-edge automated grouting detection and equipment status monitoring technologies.