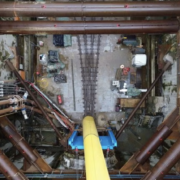

The last TBM of HS2 with 125m length has been commissioned to excavate tunnels for the new high-speed railway in the West Midlands and it has commenced its journey to dig the second bore of HS2’s Bromford Tunnel, between the east portal at Water Orton in North Warwickshire and the west portal at Washwood Heath in Birmingham.

Taking high speed trains in and out of Birmingham, this twin-bore tunnel is 5.6km long and will have a series of viaducts between Washwood Heath and Curzon Street Station taking trains to the city centre.

Following completion of the 1.6km twin-bore Long Itchington Wood Tunnel in Warwickshire last year, TBM Dorothy was reused to constructe majority parts of TBM Elizabeth, including the gantries and the centre part of the cutterhead.

Considering that trains are due to be travelling slower on the approach to Birmingham Curzon Street Station, the Bromford Tunnel with 8.62m diameter is smaller than the 10m-diameter Long Itchington Wood Tunnel. For this reason, TBM Elizabeth needed a new outer part cutterhead and a new shield, which were manufactured by Herrenknecht.

TBM Elizabeth is named after Dame Elizabeth Cadbury, who spent her life campaigning for the education and welfare of women in Birmingham.

TBM Mary Ann as the first TBM was launched in June 2023 and has completed around one-third of the drive towards Birmingham, whereas its path of drive was beneath the Park Hall Nature Reserve and is currently near the River Tame. It will continue adjacent to the M6 motorway at a depth of 27m before breaking through at Washwood Heath later this year. The determined date for completion TBM Elizabeth’s journey is autumn 2025.

The responsibility of delivering full Bromford Tunnel program is up to almost 450 people working for HS2’s contractor Balfour Beatty Vinci (BBV) and this is the fourth and final TBM launch for this contract. A tunneling team working for BBV’s sub-contractors Tunnelcraft and Solihull-based Rorcon are operating both TBMs around the clock.

According to senior project manager of HS2, Catherine Loveridge: “The project was now at peak construction, using many local companies and local skills.”

Tunnelcraft has recruited nine tunneling apprentices, including formerly unemployed people from the local area.

“This massive feat of engineering is providing a unique opportunity for people from the local area to work with us, learning new skills and qualifications in the process. We have a range of entry role positions still available and would encourage local people to get in contact. There has never been a more promising time to start a career in UK tunnelling,” said Tunnelcraft managing director Cormac Hicks.

In order to providing specialist tunnel labour for the Bromford tunnels, BBV granted Solihull-based Rorcon a subcontract in 2023, while it has around 60 people, including one apprentice, working on the Bromford Tunnel program.

The amount of removed materials by both TBMs will be a total of 1.87 million tonnes, which is sifted at the on-site slurry treatment plant and reused on HS2’s nearby sites at Delta Junction, where a network of 13 viaducts is being built. Comprising an access off the M6/M42 link roads, in order to take lorries off public roads, HS2 has built dedicated roads between the construction sites.

Using 5,942 rings to make the twin bore tunnel, both TBMs are slated to install a total of 41,594 concrete segments. Each ring weighs 49 tonnes and the segments are being produced at BBV’s pre-cast factory at Avonmouth near Bristol.