Snowy Hydro’s delayed tunnel boring machine will restart work soon, following ground stabilization works and the construction of a slurry treatment plant.

In December, TBM Florence, excavating the headrace tunnel on Australia’s Snowy 2.0 project, was transitioning from a soft material into harder rock conditions when a depression developed on the surface above the TBM.

At the time, Snowy Hydro declared that the tunnel integrity had not been compromised, and tunneling was resuming while work to remediate the surface depression was done. Also, a safety exclusion zone was set near the surface depression.

Subsequently, it communicated that the tunnel boring machine was halted temporarily while remediation schedules were finalized.

In May this year, the NSW (New South Wales) government set conditions for Snowy Hydro before tunneling could resume.

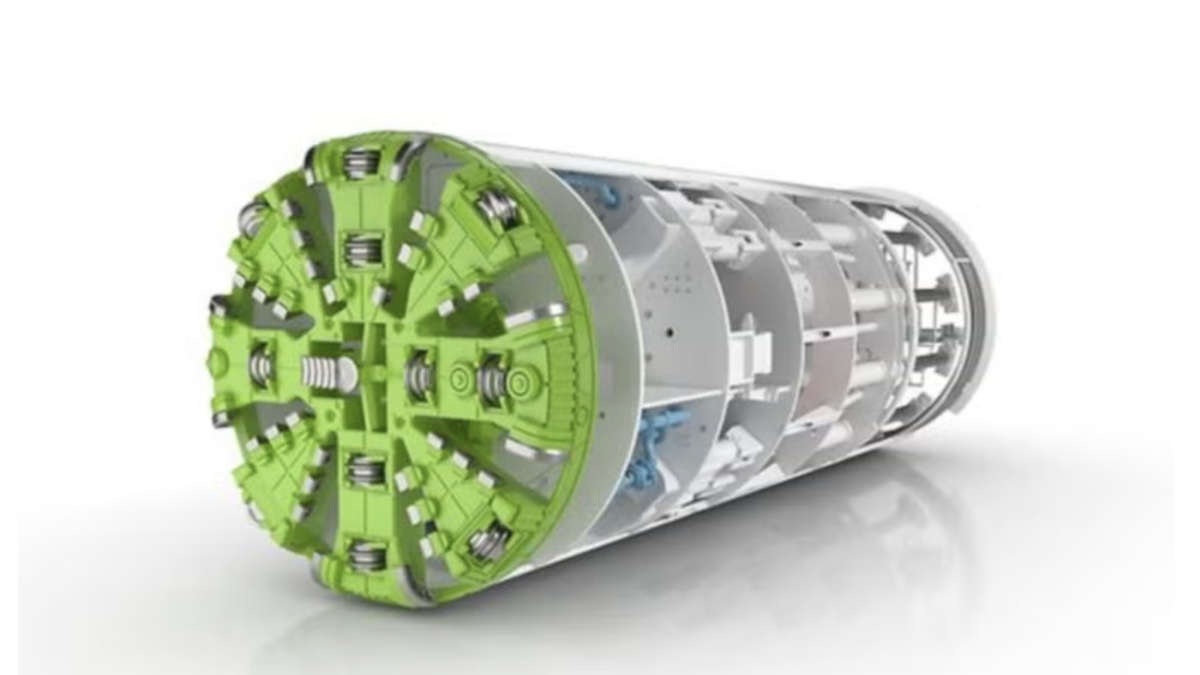

Now final commissioning tests are ongoing for the onsite slurry plant which means the dual-mode TBM can switch from open excavation to a closed, pressurized mode. This option will promote stable excavation and efficient progress via softer ground conditions when needed.

Snowy Hydro articulates that a considerable testing regime has approved grouting and stabilization of the loose material around TBM Florence has been effective.

Further stabilization continues from the surface to thicken loose material above the TBM and directly in front of the machine cutter head and the rock mass the TBM is near.

Snowy Hydro stated: “We’re carrying out rotations of the cutter head and minor advances of TBM Florence to ensure the machine is correctly positioned for final commissioning and to confirm the ground support activities are working.

“Additionally, we are working with NSW departments on environmental approvals for remediation of the surface depression above TBM Florence and to assure that this will not reoccur.”

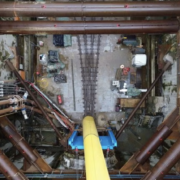

Simultaneously, an 11m diameter tunnel boring machine, Lady Eileen Hudson, has been launched on its second tunnel drive. The machine was the first to begin tunneling and complete a tunnel when it broke through on the 2.85km principal access tunnel at Lobs Hole in October last year.

The tunnel boring machine was reassembled with new parts after being recovered. In addition, the grout batch plant, chiller plant, and conveyor stacker were resettled from the key access tunnel portal to the Talbingo adit.

It is worth mentioning that TBM Eileen is 137m long and weighs 2,300 tons. The 378-tonne cutter head includes 70 cutting discs, each weighing 290kg.

The machine will now bore the 6km tailrace tunnel to link Talbingo Reservoir to the underground power station complex. Water used to induce 2,000MW of power from Snowy 2.0 will flow out of the tailrace tunnel. Also, water enters this tunnel when the power station is pumping.

Over 27,000 concrete segments produced at the Polo Flat, Cooma, the precast facility, will be employed to line the tailrace tunnel.

Snowy 2.0 is Australia’s most considerable renewable energy scheme. It will connect Tantangara Reservoir (top storage) with Talbingo Reservoir (bottom storage) via 27km of tunnels and a power station with pumping capabilities. This project will allow water to be discharged for energy generation at peak times of demand and pumped back to the top storage when there is excess renewable energy in the system, ready to generate again.