Patel Engineering Limited (the tunneling contractor) awaits the 3.2m diameter Terratec Open TBM’s arrival to Maharashtra’s construction site after the machine completed FAT with success.

The proposed TBM features a modular design that can be deployed and revived after finishing tunneling either through the shaft or disassembly underground.

Cutter head installed on the Tunnel Boring Machines features 18 heavy-duty back-loading disc cutters. The VFD controlled electric motors enabling the cutter head to rotate at over 10rpm with optimum torque.

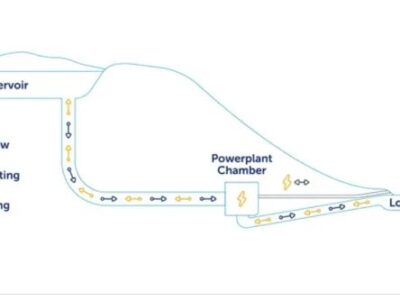

The machine will be launched two times 5,350m to excavate a 2.5m diameter corridor, stretching from Amar Mahal (Hedgewar Udyan) to Trombay Low-Level Reservoir toward Trombay High-Level Reservoir.

Additionally, in order to avoid any challenges during tunnel boring, the TBM is provided with a ground supporting equipment, a fixed probe drilling unit, two rock bolting drills, and a steel arches erector.

Mumbai’s Water Tunnel Project is among numerous measures driven by MCGM toward more favorable wastewater management, especially with the population growth resulting in a decreased demand for sustainable wastewater overflows methods.

Terratec continues to dominate the Indian market after multiple metro project achievements in Delhi, Lucknow, Ahmadabad, Mumbai, and Pune.