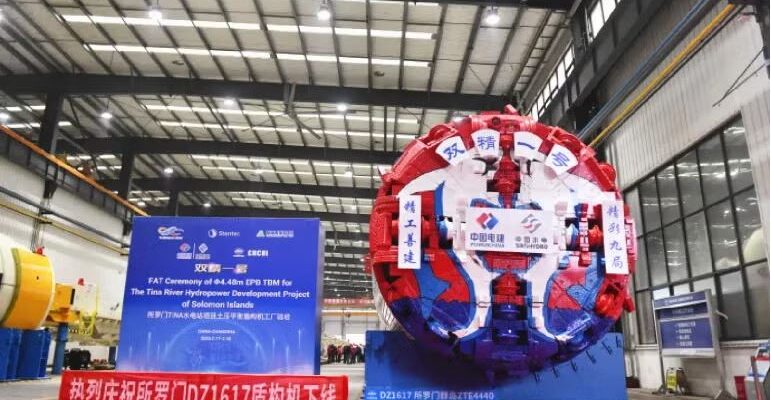

The tunnel boring machine (TBM), Shuangjing No.1, which has been manufactured by CRCHI with an excavation diameter of 4.48m, at the second industrial park in the city of Changsha, in Central China’s Hunan Province, was exported to the Solomon Islands by China’s Railway Construction Heavy Industry Corp. (CRCHI).

The aim of exporting Shuangjing No.1, the first Chinese-made TBM exported to the Solomon Islands, is to construct a diversion tunnel at the Tina Hydropower Station.

Being located in the Malango region of Guadalcanal Province in the Solomon Islands, the Tina Hydropower Station is currently under construction and the responsibility of managing its construction is up to the government of the Solomon Islands, with financing and support from several partners, including financial institutions and governments.

With almost 3.2km length, the diversion tunnel for the Tina Hydropower Station is running through geological formations primarily composed of gravel and sandstone.

Considering that the long-distance tunneling, crossing fractured rock zones, as well as high-pressure water conditions during excavation are the several engineering challenges of this project, the development team at CRCHI has incorporated several targeted designs to mitigate these engineering challenges.

Being designed with a composite cutter head engineered for hard rock excavation, increased thrust and torque capacity, and integrated pressurised manlock, Shuangjing No.1 also features intensive backup support and an advanced geological prediction system, to enhance its adaptability to different geological conditions.

Currently, the development of Tina Hydropower Station is on track with the completion and commercial operation expected in early 2028.

Providing 68% of the electricity demand of the Solomon Islands’ capital city Honiar, and promoting local economic and social development, will be the advantages of this Hydropower Station following completion.

In order to advancing the tunnel construction project for Zambia’s Chambishi Southeast Ore Body, CRCHI exported a TBM produced in Changsha to Africa in previous month.

With an excavation diameter of 5.63m, a length of about 130m and a total weight of around 800 tonnes, this machine features a minimum horizontal turning radius of 50m, which allows it to be operated on gradients of up to ±15 degrees.

The project includes excavating a 9.7km tunnel, as part of Africa’s digitised mining initiative.