In order to advancing the 116.1 km Chennai Metro Rail Phase-II Corridor 3 project in India,TERRATEC TBM S81B celebrated its first tunnel breakthrough at Otteri Station.

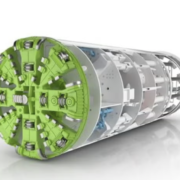

Following the breakthrough of the 6.61m diameter Earth Pressure Balance Tunnel Boring Machine (EPBM) named Kolli, TERRATEC, that is a leading provider of tunnel boring machines (TBMs), celebrated a significant landmark on the prestigious Chennai Metro Rail project in India.With attendence of representatives from the project owner, Chennai Metro Rail Ltd. (CMRL), and the contractor, Tata Projects Ltd, the breakthrough event, was held at the end of August.

Developing the Corridor-3’s underground section from Venugopal Nagar Station to Kelly’s Station, will be up to TERRATEC TBM S81B Kolli and six other TBMs, that the will play a pivotal role in the construction of almost 9 km of twin tunnels (totalling 18 km). The date of commissioning this TBM from Chennai Metro Line-3’s Ayanavaram Station South Shaft was July 2023 and achieved its breakthrough after 13 months of continuous operation, digging 903m of up-line towards Otteri Station.

Considering that as a the underground section this project is due to connect vital areas of the city and provide a fast and efficient transportation solution, it is a significant step forward for the Chennai Metro Rail network. Providing five of the seven TBMs required for this critical package, TERRATEC demonstrated their commitment to delivering exceptional tunneling solutions.

Additionally, other TERRATEC TBMs have also achieved breakthroughs on the project. In August 2023 TBM S96 achieved its breakthrough at Madhavaran High Road, whereas TBM S98 accomplished its breakthroughs in June 2023 and June 2024, at Venugopal Nagar Station (of Line-5) and Otteri Station respectively. Moreover, celeberation of TBM S99 for its breakthrough was held in September 2023 at Venugopal Nagar Station.

With intention of timely and efficient completion of this vital project, TERRATEC’s TBMs are crucial for this project that is slated to revolutionize transportation in Chennai.

The Chennai Metro Project Phase 2, Corridor 3, Package, TU01 encompasses a complex range of construction tasks, including diaphragm walls and the creation of entry and exit structures for Madhavaram Milk Colony Station, Murari Hospital Station, Ayanavaram Station, and Purasaiwakkam High Road Station, whereas it also involves the establishment of launching and retrieval shafts at these stations.Also the challenge of tunneling beneath historical structures in densely populated areas will be in the path of this project.

In order to handling various geological conditions, including sand, silt, clay, and weathered rock, TERRATEC’s TBMs are equipped with versatile mixed-ground dome-style cutterheads.The TBMs progress with the installation of 1,400mm wide and 275mm thick universal reinforced concrete lining rings, comprising five segments and a key, ensuring stability and structural integrity throughout the tunneling process.

As a after-sales assistance guarantees, to ensure optimal machine performance and successful project completion, TERRATEC’s highly experienced Field Service staff provide constant on-site support, that is a high-quality service throughout the project lifecycle.

Considering that Chennai is a city grappling with rapid population growth and escalating traffic congestion, urgently required a modern and efficient public transportation system, hence for providing this pressing need, the Tamil Nadu government launched the ambitious Chennai Metro Rail Project, aiming to provide residents with a convenient, affordable, and reliable means of transport. This major undertaking is scheduled for completion within a demanding four-year timeframe.

Including Phase III of the Delhi Metro, Lucknow Metro, Ahmadabad Metro, Kanpur Metro, Surat Metro, Pune Metro, and Mumbai Metro, TERRATEC, which is a leading provider of tunnel boring machines (TBMs), has a proven track record of delivering successful projects across India. TERRATEC’s commitment to providing tailor-made, robust TBM designs, coupled with prompt on-site assistance, readily available spare parts, and highly-skilled specialist support throughout the tunnelling process, has been instrumental in their consistent success. This expertise is now being applied to the Chennai Metro Rail Project, ensuring a seamless and efficient construction process.