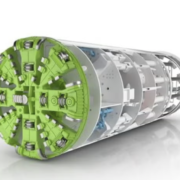

In order to being used in the construction of the local metro system, a 6.35m diameter TBM passed it’s Factory Acceptance Test (FAT) at CRCHI’s second industrial park in Changsha on September 12 and it is slated to be shipped to Cluj-Napoca, Romania.

While this is the first time that a Chinese-made TBM has been exported to Romania, for advancing the Cluj-Napoca metro project two Chinese-made TBMs have been purchased and they are going to be used in the construction of the tunnel between St. Mary’s Station and United Europe Station.

Considering that this machine is required to undertake a single-line long-distance excavation of 5.6 kilometers over the process, and will pass through complex geological conditions such as sand, gravel, salt mines, and five fault zones, while overcoming challenges such as continuous excavation through sticky soil and making turns with a small radius of 175 meters, the CRCHI’s R&D team made targeted design including a four-arms large-opening composite cutter head, multiple soil conditioning systems, advanced ground improvement through probe drilling and grouting, and an active articulation system to ensure that the TBM’s performance meets the demands of the project and addresses these challenges such as long-distance tunneling, complex strata, and the risk of clay clogging on the cutter head.

With almost 21 kilometers stretch the Cluj-Napoca metro tunnel has 19 underground stations and one above-ground station.