The TBMs that are due to build the Polihali Transfer Tunnel on Phase II of the Lesotho Highlands Water Project, have inspected by engineers and tunnel experts from the Lesotho Highlands Development Authority (LHDA).

As one of the main works components of Phase II, the Polihali to Katse transfer tunnel is 38km-long.

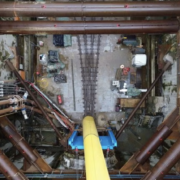

The responsibility of implementing factory acceptance test, which took place at a CCCC Tianhe plant in Changshu City, Jiangsu Province, China was up to by LHDA senior engineers, tunnel designer Metsi a Senqu Khubelu Consultants, Kopano Ke Matla joint venture, which is constructing the tunnel, and TBM designer Robbins.

According to Phase II senior projects engineer Neo Thinyane: “We verified the design of the TBMs, their functionality and adherence to safety standards. This included examining the cutterheads, back-up systems and segment erection mechanisms.”

Additionally, assessment of the muck removal system, conveyor belts, power supply, ventilation, water supply and dewatering systems was done by this team.

Considering that the TBMs are equipped with refuge bays containing life-support systems, including first-aid kits, oxygen tanks, respirators and air filtration systems, the inspection also focused on safety features, including walkways, head clearance, gas detection systems, and fire detection and suppression. Also in order to ensuring uninterrupted operation in the case of power outages, there are also back-up power and cooling systems.

The scheduled date for arrival of 5.39m diameter TBMs, which have been designed to handle the challenging basalt rock formations in the Mokhotlong and Leribe districts, in Lesotho is later this year.

Using both boring and drill and blast, the Polihali Transfer Tunnel is slated to transfer water by gravity from the Polihali reservoir to the Katse reservoir. The tunnel works include intake and outlet works, a gate shaft at the existing Katse reservoir with an underwater connection to the lake, and access adits to the waterway and construction infrastructure.