The construction of HS2’s longest tunnels – stretching for 10 miles beneath the Chilterns – achieved a pivotal milestone this week, with mining completed for 19 out of 38 emergency cross-passages connecting the northbound and southbound tunnels.

When completed, the tunnel is said to carry high-speed trains between London and the West Midlands at up to 200mph (320km/h) speeds, freeing up space on the busiest part of the West Coast mainline and enhancing journeys between Britain’s two biggest cities.

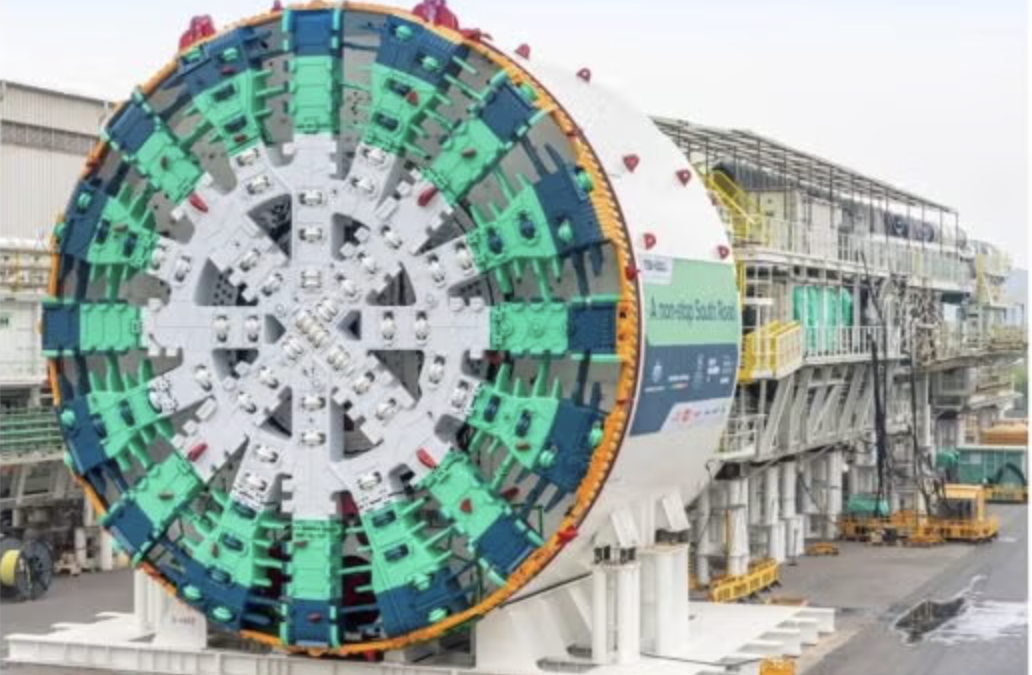

The trains will travel via two parallel tunnels connected by short passages for use in emergencies. Unlike the main tunnels, which two giant tunneling machines – Florence and Cecilia – excavated, these smaller cross-passages are bored by utilizing remotely controlled mini-excavators.

An expert team of miners use the excavators to break out of the southbound running tunnel and excavate the 15-20 meters to the neighboring northbound tunnel. As the boring advances, the ground is supported using a sprayed concrete lining (SCL).

When the team has completed the SCL lined tunnel, a water-proof membrane is installed followed by a secondary concrete lining made by placing concrete behind formwork installed in the cross passage.

HS2 Ltd’s Project Manager, Aaron Harrison, declared: “We’re making great progress on the Chiltern tunnel with approaching 9 out of 10 miles complete, and our cross-passage teams are catching up fast. Once completed, HS2 will dramatically improve journeys between London and the West Midlands, unlock tens of thousands of new homes, and free up space on the busiest part of the West Coast Main Line.”

He continued: “While invisible to the traveling public, these hidden passages have a key role in providing a safe operational railway, so it’s great to see such good progress.”

HS2’s main works contractor, Align – a JV composed of Bouygues Travaux Publics, Sir Robert McAlpine, and VolkerFitzpatrick, also responsible for the nearby Colne Valley Viaduct, will deliver the Chiltern tunnel.

Align’s Underground Construction Director, Didier Jacques, also stated: “I am delighted with the progress made by our cross-passage team, working in close cooperation with our supply chain partners. In particular, I would like to acknowledge the contribution from KVJV, who is responsible for the ground treatment, specialist contractor Euro Diamond Drilling, and waterproofing specialist Renesco.”

When the cross-passages are complete, they are temporarily sealed for fire safety reasons before permanent safety doors can be installed at either end. Bolton-based Booth Industries, who succeeded in the contract to deliver over 300 units for all the tunnels between London and Birmingham, manufactured these products.

The success enabled Booth Industries to launch a new facility in the town and generate up to 50 jobs over the next ten years. The sliding doors have been subjected to rigorous fire and fatigue testing to take account of the high train speeds, associated pressures, and frequency of the trains.

Each running tunnel has an emergency walkway that enables passengers to safely evacuate the train and walk through the cross passages into the other tunnel, where they can be rescued on a passenger train.

Accessing to emergency services will be from either the portal or one of the five ventilation/emergency access shafts. A further five short tunnels, known as ‘adits’, that connect the shafts to the running tunnels are also under construction by the team, with the mining on two of the adits already finished.

As predicted, Florence and Cecilia will break through at the north portal early next year.