Tunnel boring machines (TBMs) have a standing for being expensive and lumbering. However, innovations in the sector are boosting the speed at which they can operate, automating processes, and improving their ability to monitor complicated geotechnical conditions.

Contemporary innovations contain:

1) Harnessing the Industrial Internet of Things (IIoT):

Tunnel boring machine operators must be able to take remedial measures if geotechnical conditions alter. A machine can have up to 5,000 sensors, collecting data at different rates on metrics such as cutting surface performance, advanced progress, and cutting wheel torque.

Herrenknecht, the TBM manufacturer, lately designed a new IIoT platform to collect and manage data from wireless sensors and store it in a cloud-based central storage database.

The platform supports over 2,000 TBMs, of which up to 700 can be in the field at any one time. The data is kept on computers in the control room of the machine and uploaded to the cloud when there is internet connectivity – with the TBMs working up to 10-15km underground – they can be offline for days, weeks or even months.

In addition, the company has uploaded 40 years’ worth of historic data in various formats to the platform.

2) In-tunnel diameter changes:

[embedyt] https://www.youtube.com/watch?v=gmIfyZ998YI[/embedyt]

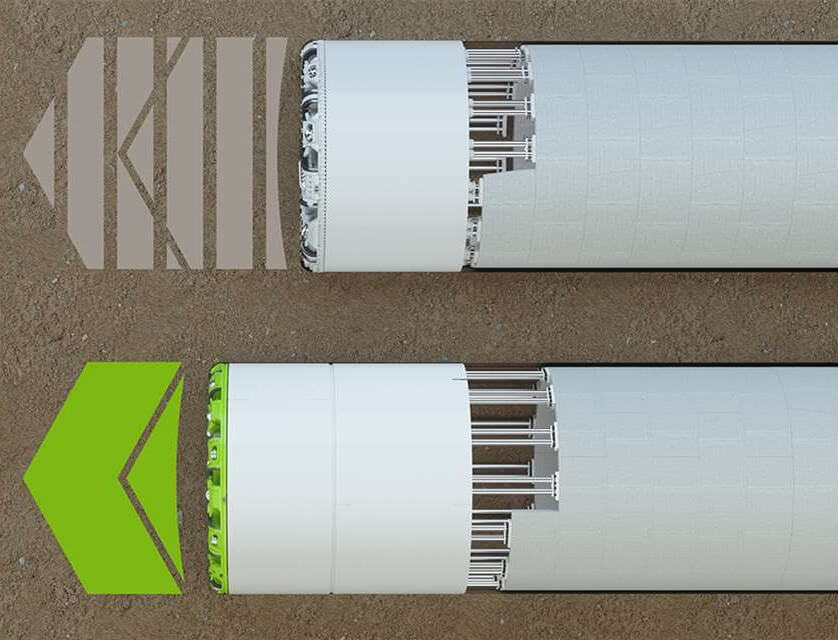

Robbins, the American manufacturer, argued an industry-first in-tunnel tunnel boring machine diameter change at the 8km-long Mill Creek Drainage Relief Tunnel in Dallas, Texas.

The tunnel has two diameters because as it moves downstream, the flow requirements rise. Correspondingly, the machine was invented to go from 11.6m in diameter to 9.9m.

Robbins collaborated with the Southland/Mole JV to design a fully smaller machine and then made a ‘kit’ that served as a larger second skin.

When the time arrived to decrease the diameter of the machine, it simply pulled the second skin of the TBM in a process that took almost four months.

3) Autonomous TBMs:

[embedyt] https://www.youtube.com/watch?v=PZpP4eQCeAA[/embedyt]

MMC-Gamuda, the Malaysian infrastructure firm, has designed what it asserts is the world’s first autonomous TBM (A-TBM) as a way of stopping its dependence on scarce tunnel-boring machine operators.

It used the second line of the mass-rapid transit (MRT) project in Kuala Lumpur as a trial bed.

The plug-and-play system merges into the current tunnel-boring machine hardware and sensors. It observes the TBM’s processes and sends the data to a centralized control center.

At first, MMC-Gamuda experimented with the technology on a single TBM to control its steering before extending it to other control parameters, like slurry controls and advance rates.

Finally, 10 of the 12 tunnel boring machines on the project were installed with the A-TBM system, excavating through different ground conditions. MMC-Gamuda conveyed the next step will be to analyze tunnelling data and to enable the system to make forecasts to deliver better tunnelling solutions.

4) Continuous tunnelling in soft ground:

A method has been developed by Herrenknecht that enables constant tunnelling in soft ground formations.

Tunnelling has traditionally had to halt after each boring stroke to enable the tunnel ring-building sequence to occur.

The new constant tunnelling system, which is 1.6 times faster, catches those thrust cylinders that push the TBM forward during the advancement and take over the force share of the cylinders that are rescinded for ring building.

A computer-driven Center of Thrust (CoT) system gain control of the pressures in the thrust cylinders from a manual operator to make sure that the TBM keeps its correct course during this process.

Herrenknecht received the Bauma Innovation Award 2022 in the ‘Machine Technology’ category for its new outcome.

5) ‘Porpoising’:

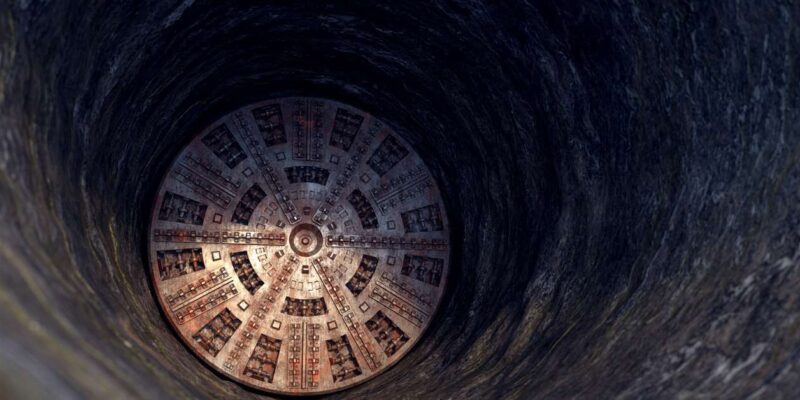

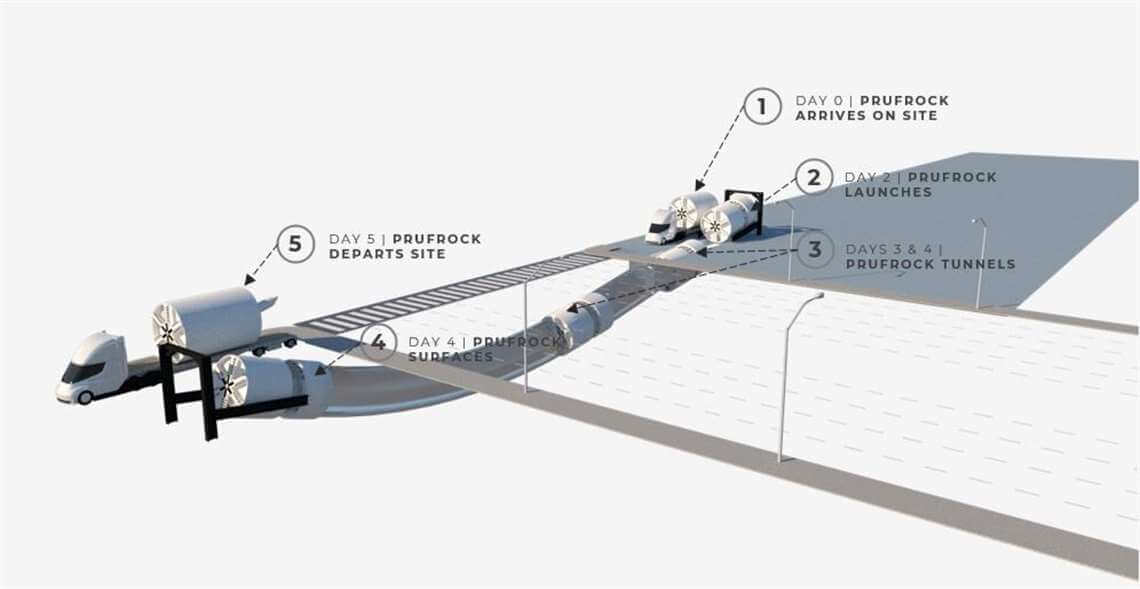

Elon Musk’s Boring Company launched the second iteration of its ‘Prufrock’ tunnel boring machine in 2022.

The Prufrock is developed to launch directly from the surface, excavated underground and re-emerge on completion, removing the necessity to bore pits to launch and retrieve the TBM, in a process known as “porpoising”.

The Boring Company declares that it can tunnel at a speed of one mile per week via soft ground, which is up to six times quicker than its last generation of tunnel boring machine, the Godot+. The medium-term objective for Prufrock is to tunnel at a rate of seven miles per day.

6) Plasma and superheated gas:

Earthgrid, the San Francisco-based start-up firm, is developing a plasma micro tunnel boring machine for the markets of energy and utilities, that it argues can excavate underground 100 times faster than traditional methods.

Its plasma torches reach temperatures of 27,000C to blast through hard rock. The torches are mounted on discs held out in front of a ‘rapid burrowing robot’ to blast away fragments backwards to be assembled in small push carts.

Moreover, Petra, the US-based start-up, has designed an independent robot called Swifty, that can excavate small tunnels between 40cm and 1.5m in diameter through hard rock for utilities. It uses a proprietary mix of superheated gas up to 1,800C.