Align Joint Venture’s two TBMs boring High Speed 2’s 16km long Chiltern tunnels have passed the Amersham vent shaft site in Buckinghamshire.

Since being launched in the spring and summer of 2021 from a site near the M25, the tunnel boring machines – Florence and Cecilia – are nearly 9km into their 16km drives beneath the Chilterns.

Now they have passed the third of five ventilation and emergency access shafts along the route right after lately hitting the halfway mark.

The machines are boring the twin tunnels between the M25 and South Heath in Buckinghamshire on the first phase of the High Speed 2 (HS2) scheme. Align is operating the machines and is a JV comprised of Bouygues Travaux Publics, Sir Robert McAlpine, and Volker Fitzpatrick.

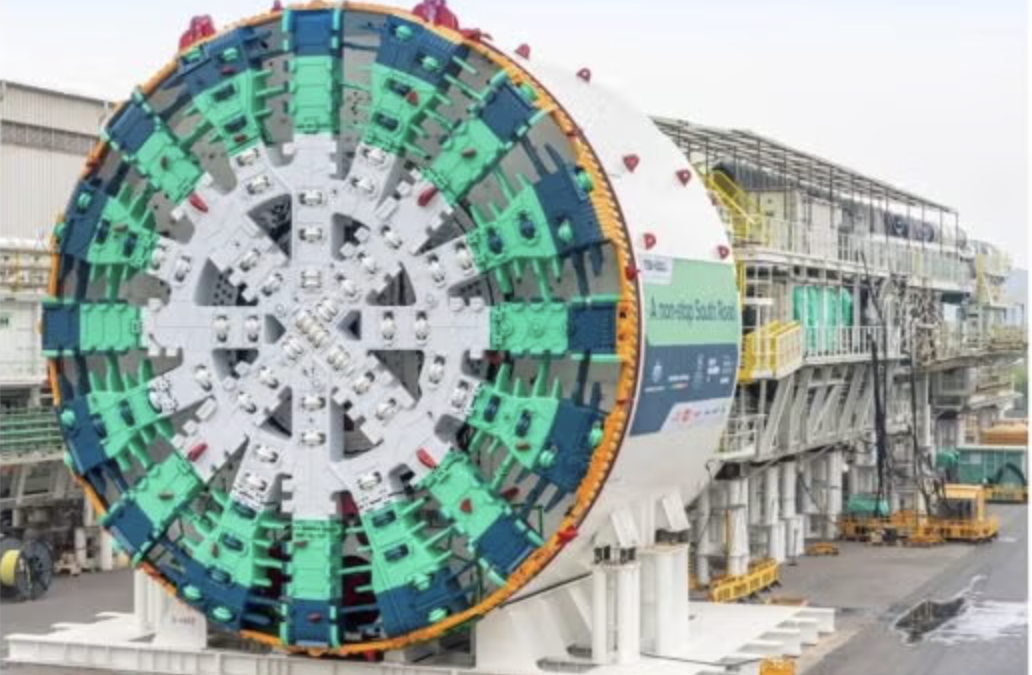

Each machine weighs 2,000t and is a 170m long self-contained underground “factory”, excavating the tunnel, lining it with 56,000 concrete segments to form rings and grouting them into place as it progresses.

The tunnel boring machines are designed particularly for the geology of the Chilterns and have dug over 1.8M.m3 of chalk and flint.

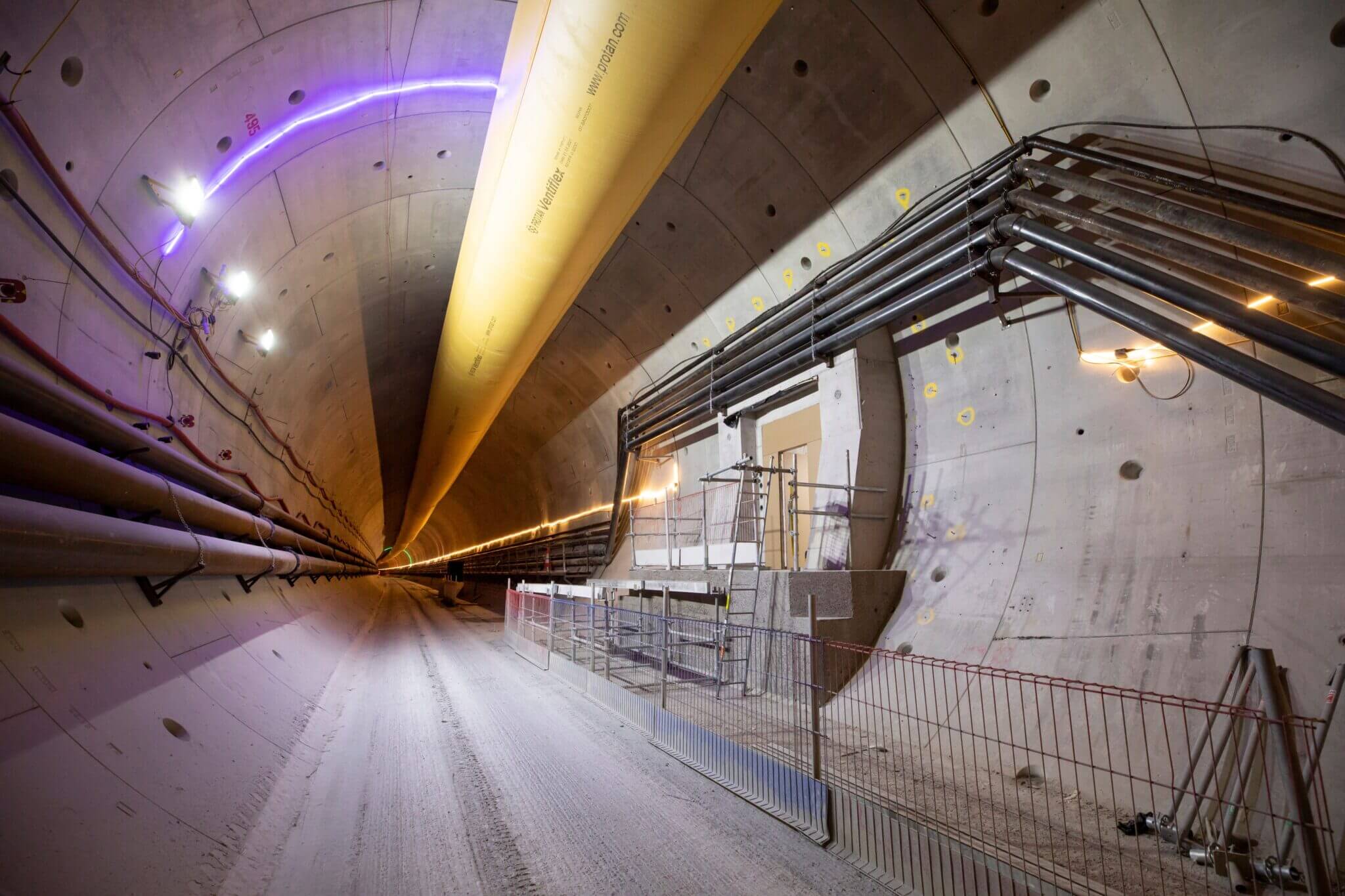

In addition to advancing the tunnels, Align’s team has also finished the boring of the shafts that will deliver ventilation and emergency access near Chalfont St Peter, Chalfont St Giles, Amersham, Little Missenden and an intervention shaft at Chesham Road.

The shaft at Amersham is 44m deep and is in the middle of a road junction just outside Buckinghamshire town. Also, a headhouse is said to be constructed on top of the shaft to house safety equipment.

Martyn Noak, HS2 Ltd.’s head of tunnel engineering, expressed he was “very impressed” with the TBMs’ progress.

He stated: “It’s great to see how much progress they and the teams excavating the five shafts have made and I’d like to thank everyone involved in getting us this far.”

Seventeen people are working on each TBM in shifts and are supported by over 100 people on the surface, managing the logistics and maintaining the advancement of the tunnelling operation.

Coralie Peroux, Align tunnel manager, pointed out: “Florence and Cecilia reaching our third shaft at Amersham is a great achievement for not only the tunnelling team and the team involved in excavating and preparing the shaft, but also the supporting teams on the surface at the south portal, manufacturing the concrete segments required to line the tunnel and processing the spoil from the tunnels.”

She also added: “In particular I would like to pay credit to the Align shafts team, working with our supply chain partners KVJV [made up of Keller Group and VSL International] and Keltbray, who have been working tirelessly over the last few months to ensure the shaft is ready for the arrival of Florence and Cecilia.”

About 2.7M.m3 of material will be bored during the tunnels’ construction and used for landscaping. When construction is done, the temporary buildings at the south portal will be removed, and the site will be landscaped with about 90ha of new chalk grassland habitats.

Now, there are five tunnel boring machines in the ground operating on this phase of the HS2 project, with an additional five due to be launched over the coming years. They will build 103km of the tunnel between London and the West Midlands, containing significant tunnels on the approach to London and Birmingham.

Last month, a machine on the project had to be stopped when a pool of foam emerged from a borehole along the route of the West Ruislip tunnel in west London.