Considering the completion of the first underground connection among the northbound and southbound tunnels, a landmark has been achieved in the construction of High Speed 2 tunnels beneath the Chilterns.

In order to carry high-speed trains from London under the Chiltern Hills, excavation of 16km long twin-bore tunnels, which are the longest on the railway project, are up to Tunnel boring machines (TBMs) Florence and Cecilia.

Following their commission in the previous summer, currently the machines have dug almost 6km from the Chiltern tunnel’s south portal up to the ventilation shaft at the village of Chalfont St Peter and beyond.

Connecting by 38 short cross passages, the intended tunnels are due to use in emergencies, while these passages are being built by HS2 Ltd’s main works contractor, Align – a joint venture formed of Bouygues Travaux Publics, Sir Robert McAlpine, and Volker Fitzpatrick and each passage is between 15m and 20m long.

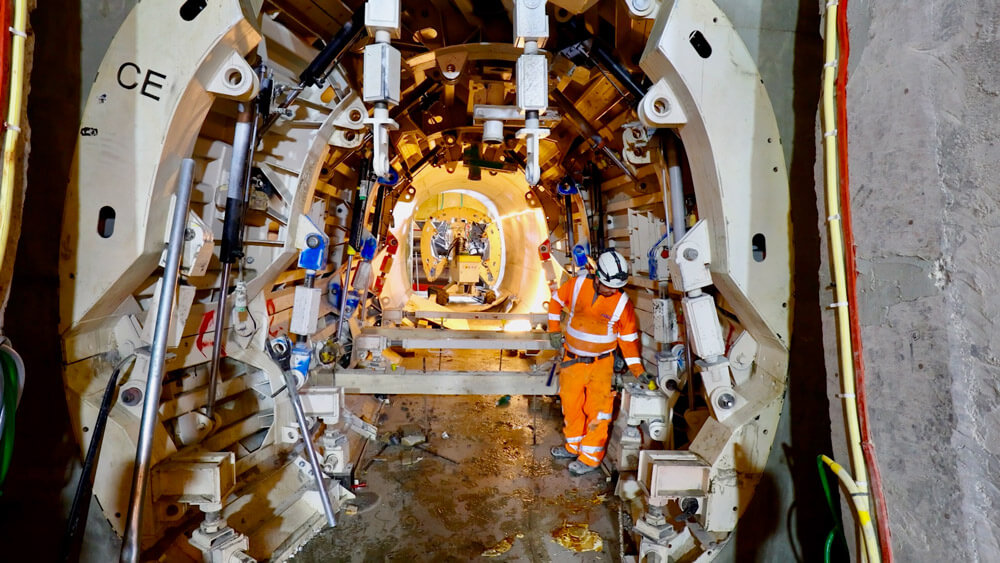

In order to break out of and excavate from one running tunnel to the adjacent tunnel, the creation of the first passage was done by a team of miners used a remotely controlled excavator, whereas supporting the ground is done using a sprayed concrete lining as the tunneling is advanced.

After the tunnel was lined, a water-proof membrane was installed followed by a secondary concrete lining constructed by placing concrete behind formwork installed in the cross passage. Once the passageway is complete, the safety doors are installed at either end.

According to HS2 Ltd’s head of tunnel engineering Martyn Noak: “While invisible to the traveling public, the cross passages have a key role in providing a safe operational railway. In an emergency, they allow the safe evacuation of passengers into a place of relative safety – the other tunnel.”

“Constructing cross passages is different than using a tunneling machine as the ground is excavated in short lengths with each advance being left unsupported for a short period of time until the sprayed concrete lining is installed. It is a different set of risks and a specific skilled workforce is needed,” added Martyn Noak.

Align project director Daniel Altier said: “The completion of this cross passage is a significant milestone for the team at Align JV, delivering the first mined cross passage on HS2 phase one. I’m proud of the team, their hard work and collaboration to get us to this point.”

He continued: “In partnership with our supply chain – KVJV responsible for the ground treatment, specialist contractor Euro Diamond Drilling and waterproofing specialist Rennesco – the sub-surface team at Align have already commenced preparation work on several other cross passages and are making good progress.”

Completion of diaphragm walling on the tunnel shafts was done towards the end of last year, while there are four ventilation shafts and one intervention one, with 3km between them.

Stretching between London and the West Midlands, including major tunnels on the approach to London and Birmingham, boring more than 103km of the tunnel will be done using ten TBMs on the HS2 project. Also, three machines have been launched so far.