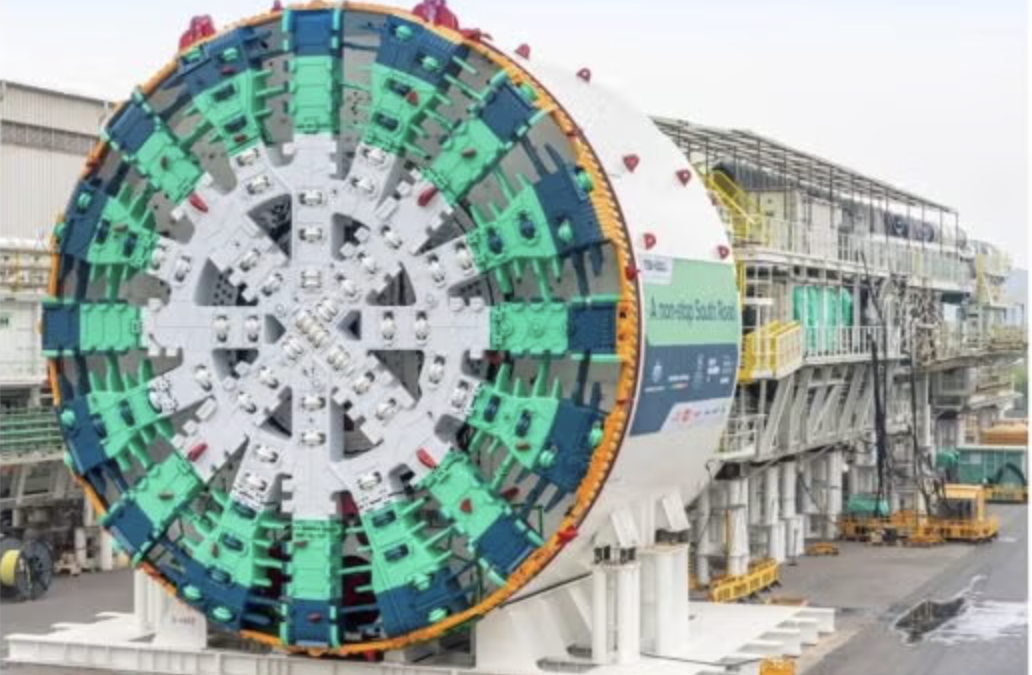

The digging process of the Seosan cable tunnel project in South Korea has been completed by a slurry TBM jointly developed by CRCHI and HOBAN.

With a maximum slope of 1.3%, the 2.044km tunnel has a continuous uphill gradient and traverses complex geological formations including hard rock and weathered rock, with a minimum horizontal curve radius of 120m and rock compressive strength reaching up to 71MPa.

In order to ensuring efficient equipment delivery, CRCHI (China Railway Construction Heavy Industry Corporation Ltd) conducted in-depth investigations of South Korea’s construction environment and optimised the solution by incorporating local characteristics over the design phase.

Also a tailored solution featuring a double-articulated steering system, an efficient rock-cutting solution, and a high-capacity slurry circulation system was developed by CRCHI’s R&D team to address the challenges of long-distance hard rock tunnelling and the tight 120m-radius curves.

In addition, the machine was equipped with an ultra-low clearance segment hoist and a side-mounted coiled pipe extension system.

As the fourth TBM CRCHI has exported to South Korea, this shield TBM has a 3.26m excavation diameter and is 135m long.

In corporation with HOBAN, the CRCHI team helped to ensure efficient project execution, successfully overcame complex geological challenges, and achieved a monthly advance rate of 223m.