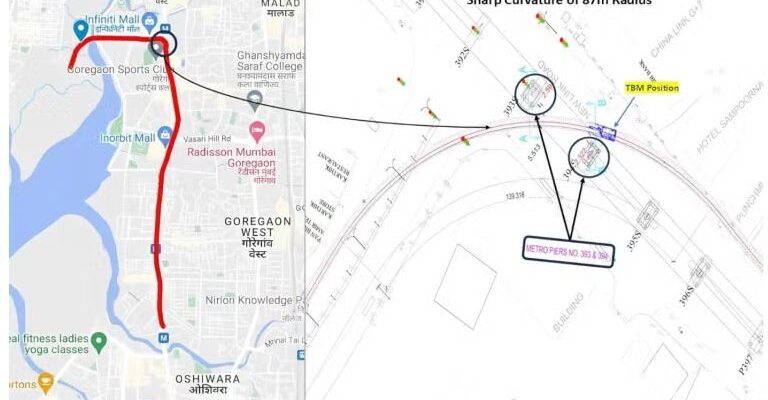

A sharp 87m radius curve for the Mumbai Sewage Disposal Project has been completed by a Terratec rock EPBM.

Being located between Goregaon Pumping Station and New Malad IPS, the 4.6km-long Priority Sewer Tunnel-Phase 2’s engineering feat was reached by hte 3.14m diameter TBM S116,whereas this achievement sets new standards for urban tunneling in constrained environments, as Terratec says.

Considering that in this project advancing a tunnel through a sharp 90-degree curve beneath a busy road junction, without the use of a shaft, was done, the project posed a significant engineering challenge.

Over live train operations, the TBM had to maintain millimetre precision while navigating just 2.3m of clearance between active metro foundation pillars. It also passed through a section with minimal overburden, encountering highly variable ground conditions, including 95MPa basalt, large boulders, and mixed soils.

The TBM also excavated approximately 500m directly beneath a creek and mangrove wetland, managing the substantial risks associated with tunneling through an environmentally sensitive area with very low overburden.

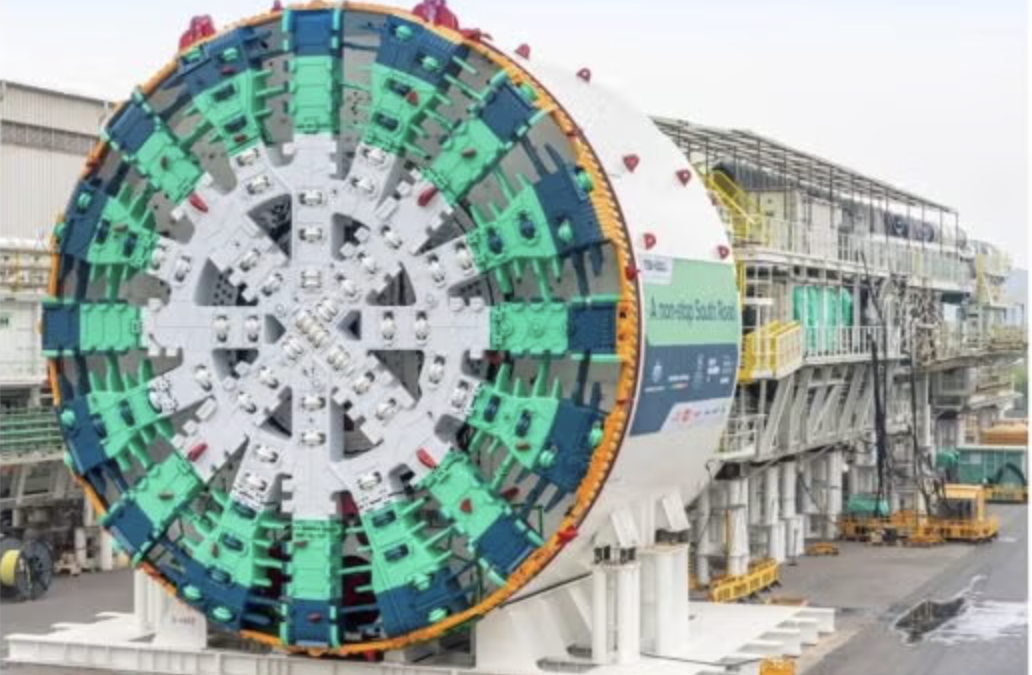

In order to enabling this achievement, deploying a purpose-built spherical articulation TBM, supported by a suite of innovative engineering solutions tailored specifically for the project was done.

Including 660mm rings for the sharp-radius curve and 1000mm segments for the straight sections, the team introduced a dual-segment lining system, whereas the boring of the tight-radius section marks a first for tunneling projects in India. Also the key modifications to the TBM included cutter disc adjustments to enable controlled overcutting, customised rolling stock to accommodate reduced clearances, and a conveyor system engineered to navigate the sharp curvature.

With the aim of preventing major traffic disruptions and substantial savings in both construction time and cost, the tight-radius solution offered significant advantages over conventional methods by eliminating the need for Shaft S10 at a congested road intersection near a shopping mall and meBeing designed to operate within extremely confined internal dimensions,this machine is the smallest segmental EPBM in its class operating in India. These constraints, although expected, were carefully addressed through detailed planning, continuous monitoring, and precise machine steering. Terratec says this controlled approach proved especially critical when navigating the hard geological formations in the curve section.

TBM S80, which previously worked on the MSDP Stage-II Priority Works and currently is digging for the Mithi River Water Quality Improvement project, is the sister of TBM S116 and shares the same design with she, while both TBMs have maintained impressive productivity, averaging 300 rings – or approximately 360m – of tunnel advancement per month.

As a critical component of the city’s wastewater management upgrade, the Mumbai Priority Sewer Tunnel is designed to significantly reduce pollution in the Mithi and Oshiwara rivers while enabling advanced water recycling processes.tro station.