Being held on April 6, at a ceremony during the opening of the trade fairwas made in the machine technology category, Herrenknecht has received the bauma Innovation Award 2025 for its Tunnel Enlargement System (TES).

According to Johann Sailer, managing partner of Geda: “Tunnel construction technology is always fascinating – this one in particular makes it possible to safely renovate and expand all railroad tunnels while rail operations continue.”

While rail operations continue, TES enables the cross-sectional expansion of existing railway tunnels.

With TES, Herrenknecht says it is tackling a key challenge of Europe’s transport infrastructure: many of the 800 or so rail tunnels that were built in Germany, Austria and Switzerland between 1850 and 1910 are still in operation – and will need to be extensively modernised in the future. Electrification, larger track gauges, modern safety standards and increasing traffic needs require the tunnel profiles to be enlarged, without interrupting train operations.

Martin-Devid Herrenknecht, member of the Herrenknecht board of management, said: “TES was setting a new milestone in mechanised tunnel construction.The combination of high technology, safety and efficiency opens up new possibilities for making existing transportation routes uninterrupted and fit for the future. I am particularly proud of our team in Schwanau, which has brought this technology to maturity with experience, creativity and the courage to innovate.”

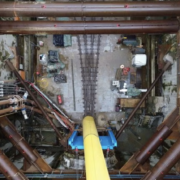

Dismantling the existing tracks, and laying a track in the middle of the existing tube are the works that are done when TES is used,whereas rail traffic continues to run safely on this track during the entire construction work. TES moves forward step by step as the tunnel is excavated. At the same time, it serves as a protective enclosure and separates the construction work reliably from the ongoing rail traffic.

While protecting the tunnel and the railway from collapse and falling rock is up to the front machine section of TES, the middle section carries highly developed excavation and safety technology, and the rear machine section supplies power, compressed air and construction materials.

In January 2024 TES was first used on a large scale for the renovation of two historic tunnels of the Lahntalbahn near Limburg an der Lahn: the 426m-long FachingerTunnel and the 732m-long Cramberger Tunnel. The tunnel cross-section was extended by around 2m in radius during ongoing rail operations.

“Porr with TES successfully enlarged the first tunnel and we are delighted that this has now been recognised with the innovation prize,” said Dr.-Ing Ulf Kirsten, Porr’s head of tunnel machine technology operational services.

Collaborating with Herrenknecht, Porr submitted TES for the industry-renowned prize.

This year bauma received 208 entries for the awards and the winners were chosen from a shortlist of 52. bauma 2025 continues in Munich until April 13.