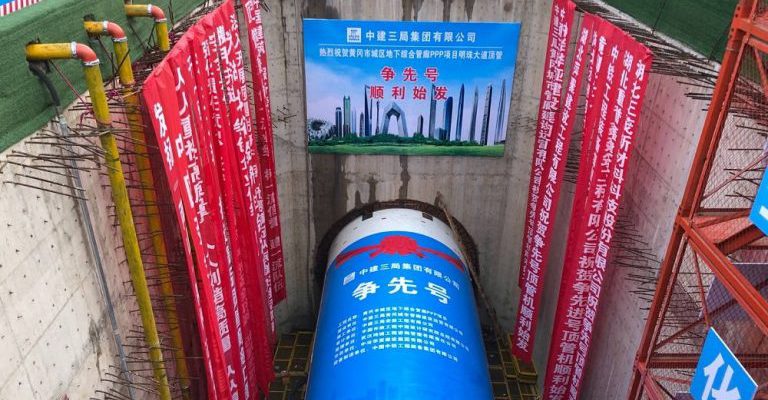

On July 27, 2020, the hard rock slurry balance pipe jacking machine (DN4000), named Zhengxian (which translates to “try to be the first”), successfully broke through on the Mingzhu Avenue utility tunnel in Huanggang City, Hubei Province, China, despite COVID-19, flood and other obstacles. The machine is independently developed by China Railway Engineering Equipment Group Co. Ltd. (CREG), and is suitable for complex geology. Currently, this project is the largest diameter utility tunnel project using a circular pipe jacking machine in China.

With the continuous development of China’s society and economy, the demand for underground space development projects such as mechanized construction of subway cross passages, large-span tunnels construction with the pipe-roofing method, and urban municipal pipe network construction and renovation are increasing rapidly. As China is known as for its diverse geology and complex hydrogeology, the tunnel alignment usually comprises variable geologies. So, the construction of small diameter tunnels in complex strata with variable ground hardness and diverse geology puts forward very high requirements for the overall performance of pipe jacking machine.

CREG successfully manufactured China’s first small diameter slurry balance pipe jacking machine (DN2800), which has totally independent intellectual property rights and is appropriate for composite strata, in May 2015. Major innovations and breakthroughs have been achieved in core technologies such as adaptable cutter head, micro-drive technology, miniaturization technology, and cutting tool changing technology for mixed ground. This machine has been successfully applied in Nanning’s municipal sewage pipeline project. The tunnel alignment is staggered with upper soft and lower hard full-face red clay and hard rock, along with karst caves. The saturated uniaxial compressive strength of limestone exceeds 110 MPa at most. The tunnel is about 3.5 km long and the maximum daily advance rate reaches 20 meter.

In October 2017, Shanghai Civil Engineering Co. Ltd. of CREC, the Scientific Research Consortium constituted by CREG, Ningbo University Shanghai, and Tunnel Engineering & Rail Transit Design and Research Institute successfully developed China’s first pipe jacking machine for cross passages. It achieved four technical innovations, including new-type curved cutter head, mechanized construction method for cross passages, movable pipe joint prestress safety support system, and high mobility and high integration. This machine has successfully been applied to more than 10 projects such as Wuxi Metro and Ningbo Metro.

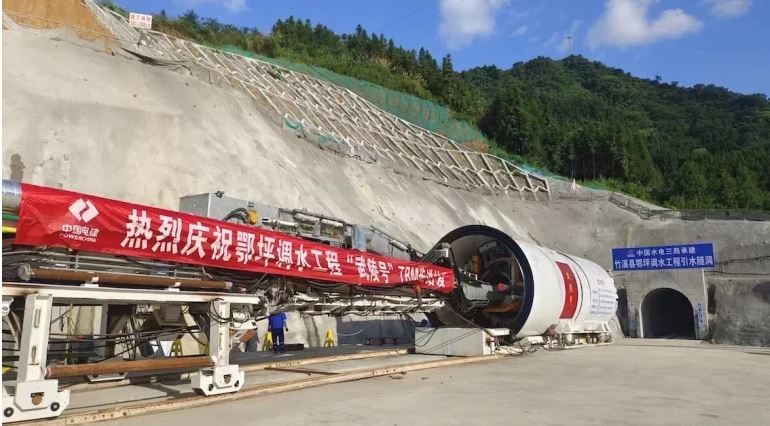

The TBM, Zhengxian, is one of the large hard rock slurry balance pipe jacking machines for complex strata worldwide and has a diameter of 4.86 m. There are several breakthroughs and innovations in key technologies, such as new-type machine and pipe joint anti-entrapment design, high-efficient slurry flushing technology for preventing filter cake, new-type tapered secondary crushing technique by displacement shear, self-adaptive attitude control technique and micro disturbance advance. In addition, CREG successfully overcame difficulties such as rock fragmentation, cutter head abrasion, local karst caves and ground settlement while achieving rapid advance rate, low energy consumption, and minimal disturbance to the surrounding area, which won the owner’s high praise.

At the moment, CREG have been applied all kinds of its designed and manufactured hard rock pipe jacking machines for complex strata in diameterd ranging from 0.3 m to 5 m to many projects, including water diversion, utility tunnel, pipe roofing, power, cross passage, and sewage, which sets a good example for promotion and application of pipe jacking method in hard rock and complex strata.

Source: Tunnel Business Magazine