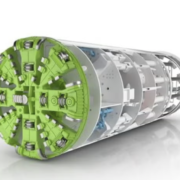

In order to enabling the TBMs to be reused on new projects as well as decreasing the company’s capital expenditure and operational costs, the Webuild‘s Equipment & Machinery regeneration factory in Terni, Italy has been launched and it is slated to service, modify and update Webuild’s TBMs.

The other advantages of this initiative, along with expanding the lifespan of the TBMs, will be reducing all costs linked to the machines and boosting the know-how to develop new technologies in future.

Covering seven railway contracts in Sicily which will require 19 TBMs, Webuild is currently working on several projects in Italy, whereas the new factory is part of a larger investment in research and training.

Considering that producing pre-cast concrete segments for two lots on the Catania-Messina route was required, Webuild has constructed a fully-automated factory in Belpasso, Catania, while a second factory near Enna will open soon. As Webuild states this is the first of its kind in Italy, and is producing a segment every seven minutes, compared with the 10 minutes required without full automation.

Building a training centre in Belpasso, which includes a TBM simulator, constructing a training venue (the Novi Ligure in Piedmont, built for the Terzo Valico dei Giovi project) focuses on traditional excavation methods and open works, are the activities of this company, while the next destination is Campania and company will specialise in mechanical tunnel excavation.