In order to advancing construction of the tunnel for the new Lyon-Turin railway, the fifth of the seven TBMs has been delivered to the French-Italian group of companies, Elyot, at Herrenknecht’s factory in Germany.

The excavation process of the longest and most complex section of the Mont Cenis base tunnel, will be up to this machine and its twin TBM, which was delivered in December,whereas this section is the 18km between the French and Italian border from the Villarodin-Bourget/Modane area to the Clarea underground safety site, in the deepest part of the tunnel where the overburden is more than 2,200m.

Considering that the intention of designing this TBM is to meet the needs of the CO5 construction site, it has several distinctive features, designed both to perform the initial lining of the tunnel and to tackle any geological difficulties.

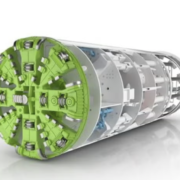

The gripper TBM has a 10.4m diameter, is 334m long, has a capacity of 4,900kW and weighs 3200 tonnes. It has two lateral grippers which clamp to the tunnel walls and four pistons then push forward on the head, which rotates breaking the rock.

Placement of a 50m-long beam in the centre of the machine allows curved beams of 25 tonnes each to be moved and laid at the base of the tunnel, where the network of underground utilities will pass.

During the digging process, shotcrete support is due to be applied to the walls, along with bolts and ribs. Behind each TBM, a 650m-long machine called the Würm (worm) will fix the final concrete lining.

Due to existence of the geology of relatively compact, uniform and stable formations; the depth of the tunnels; and geotechnical considerations, such as detachments and convergence, a gripper TBM was chosen. Additionally, there are the high temperatures present at such depths, which were highlighted by the exploratory tunnel of La Maddalena in Chiomonte, which was used to establish the TBM’s specification.

The responsibility of commissioning these two TBMs from France will be up to Elyot, which comprises Eiffage Génie civil, Spie batignolles génie civil, Ghella and Cogéis.

At the same time as the 18km-long twin tunnels are excavated, 7.8km of tunnels will be dug using conventional methods. In addition to these works, all connected and logistical works will be carried out. In total, around 15km of tunnels will be built using the conventional method, including the underground safety area at Modane.