In order to replacing a segment of pipelines on the lakebed of the Straits of Mackinac, with a single pipeline in a tunnel deep beneath the lakebed, the Michigan Public Service Commission has approved a siting application, whereas Enbridge Energy LP‘s additional government approvals, permits, as well as conditions related to the tunnel’s safety and construction, are required for this decision.

Considering that without this pipeline, suppliers would need to use higher-risk and costlier fuel supply sources and transport, the Commission found there was a public require for the replacement section of Line 5 and the light crude oil and natural gas liquids it carries.

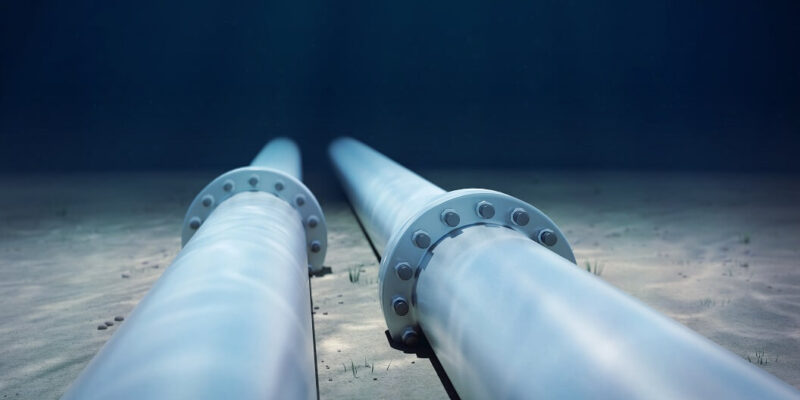

Additionally, as the order noticed there was a public need to preserving the Great Lakes’ environmental and culture resources that would be helped by replacing the existing dual pipelines, now exposed to the elements and to risks including ship anchor strikes on the lakebed. Meanwhile, increase in environmental damage and raise the risk of spills, were possible in other modes of transporting Line 5’s products, such as truck, rail, oil tanker or barges.

The Commission also found that:

- Enbridge has demonstrated that an experienced and knowledgeable firm designed the tunnel, and it will be built using state-of-the-art materials and practices that will meet or exceed industry standards.

- The replacement segment is a significant improvement over the existing dual pipeline configuration, virtually eliminating the risk of anchor strikes, in addition to the replacement segment being housed in a tunnel that can serve as a secondary containment vessel that would contain a leak if one developed.

- The Straits Line 5 replacement segment meets or exceeds current safety and engineering standards, given that the inspection procedures required by Enbridge for manufacturing and installation exceed required minimum safety standards.

Also the Commission described that the route, location, and design of the project was reasonable and should be approved, subject to conditions. In order to ensuring the safety, integrity and reliability of the Straits Line 5 replacement segment, these include exceeding minimum federal regulations. Order of Commission to Enbridge for implementing procedures for low-hydrogen welding for all mainline girth welds and to ensure that the procedures require both preheat and inter-pass temperature requirements, was issued, while Enbridge must also ensure that the mainline girth welds are non-destructively tested using automatic phased array ultrasonic testing methods.

Before Enbridge commences construction, the Commission required to submits a detailed risk management plan that includes geotechnical test bore sitings with related data and real-time reporting; results of concrete cast section inspections; placement plan of gaskets; analyses of bentonite mix, and any changes in slurry pressure.

The Commission also recommended that all equipment used in the tunnel should be designed to meet the most stringent standards for electrical equipment under the National Electric Code.

As a interstate pipeline from Superior, Wisconsin, across Michigan’s Upper Peninsula, the Straits and the Lower Peninsula before terminating near Sarnia, Ontario, Line 5 has 1,038km (645-mile) length and first was built in 1953, while its average annual capacity is 540,000 barrels per day.

In the almost 6.4km of Line 5 crossing the Straits, there are currently two, 508mm (20in) pipelines, the span of which are primarily near or on top of the lakebed. Enbridge would replace the dual pipelines with a single, 76mm (30in) pipeline in the concrete-lined tunnel with an inside diameter of 6.4m (21ft), routed through bedrock 18-113m (60-370ft) beneath the lakebed. The tunnel will have space for the Line 5 replacement segment in addition to ventilation systems, leak detectors, dewatering equipment, and equipment needed for inspections and maintenance.

In April 2020 Enbridge initially filed its application and the date that Commission asked Enbridge to file documents and any relevant information to develop a full record on tunnel engineering and safety, electrical equipment and risk of fire and/or explosion, and the safety of the current dual pipelines, including leak detection systems and shutdown procedures, was July last year.