One of the two large TBMs moving southwards in Austria, Ida, has just finished the first 1,000-metre stretch of excavation. Furthermore, while the tunnel boring machines drive their way southwards, a straightforward design choice helps protect the areas where the project is being constructed.

The BBT SE project firm remains committed to critical infrastructure construction for mobility in Europe and, simultaneously, to the natural habitat protection affected by the project.

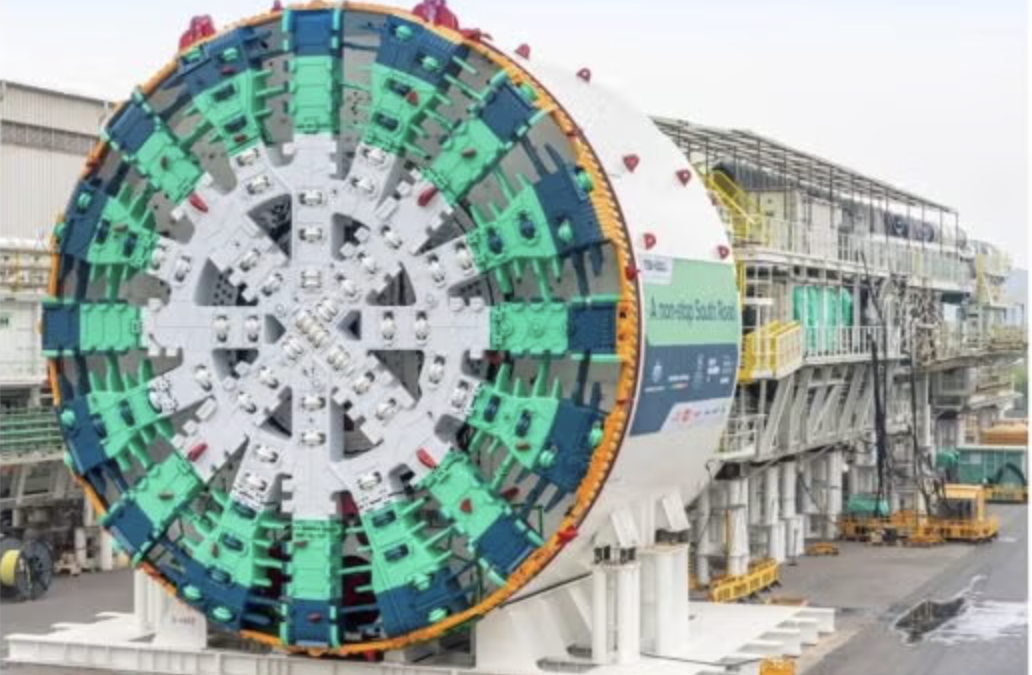

Ida started its work on 27 June and is almost to finish the first thousand meters of its journey in the west main tunnel as part of the H41 Sill Gorge-Pfons construction lot, Austria. The machine and its counterpart, Lilia, have already passed the vital fault zone called ‘Viggertal’, without any significant problems.

While excavating, the two tunnel boring machines also lay the inner ring lining of the tunnel, incorporating six concrete segments with a total weight of nearly 60 tons per ring.

As Ida goes toward the south, the excavated material must be dealt with and removed. The spoil is conveyed through a conveyor belt to the Padastertal Valley, where the most considerable disposal area for excavated material in the complete project area is placed.

This choice is neither simple nor random: it avoids thousands of truck journeys and the associated CO2 emissions into the atmosphere. For the same reason, the tubbing rings are made directly on the construction site.

This intricate system of conveyor belts, which links the Sill Gorge-Pfons lot with the Padastertal depot for a total length of over thirty kilometers, runs on electricity. Since it is located entirely underground and inside the exploratory tunnel, it does not pollute or visually impact the local population.

The residents living in the project area greatly benefit from this decision by BBT SE. Those who live around the area of the H41 Sill Gorge-Pfons site, and not only, are not influenced by the noise, dust, or traffic disturbances that the road transport of the material would have entailed.

Ivan Zamberlan, the lot controller at the H41 Sill Gorge-Pfons site, explains that as well as being a sustainable way of handling excavated material, it is also efficient. He expressed: “Thanks to the conveyor belt, excavated material can be disposed of twenty-four hours a day, seven days a week. This would not be possible if the transport was by road, given the restrictions on heavy-duty vehicle traffic on the roads.”

This long belt will move about 4.5 million tons of excavated material for Lot H41 Sill Gorge-Pfons in total, which is roughly the volume of the Chephren pyramid in Giza. Nevertheless, the Brenner Base Tunnel construction continues to be done in an efficient and environmentally sustainable manner, with an eye on the well-being of the inhabitants in the project area.