Starting up the new Snowy 2.0 precast factory in Cooma, where 130,000 concrete segments are being produced locally to line the tunnels for the major pumped-hydro project, has been commenced by Snowy Hydro and the main contractor and factory operator Future Generation Joint Venture over the weekend. Click the video for more details.

[embedyt] https://www.youtube.com/watch?v=fvXWVGKFOSw[/embedyt]

In order to create local jobs, opportunities, and investment, Snowy Hydro attempted to construct this factory locally instead of importing segments from overseas or interstate. A concrete batching plant and two automated carousels, producing up to 24 rings, each one made of nine segments, are the daily activities of this factory.

The source of providing raw materials is the local area to mix concrete within the batching plant, which is then transferred into the factory and poured into specially-designed moulds every 10 minutes. In a recycling invention, almost 70,000 tons of slag, which are a by-product of the steel manufacturing process, is used to generate the segments. Despite decreasing the amount of needed cement by 40 percent, the segments are going to supply the three Snowy 2.0 TBMs as they bore and line more than 27 km of tunnels between Tantangara and Talbingo reservoirs.

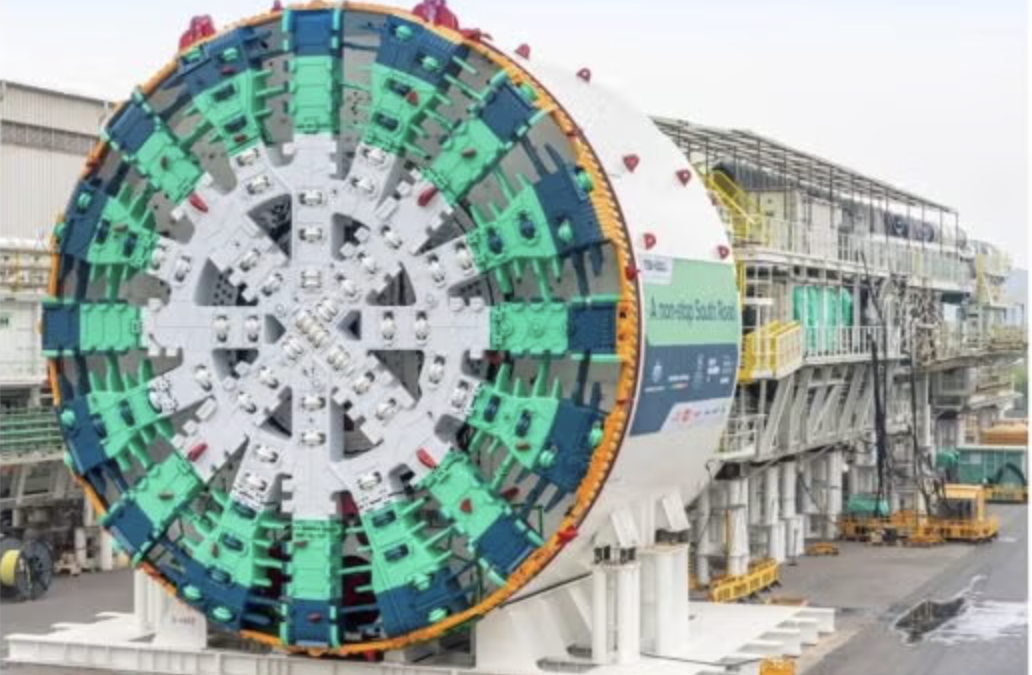

While the digging process of the main access tunnel, which now has more than 600 m wide, is undergoing using Lady Eileen Hudson TBM, the second machine, TBM Kirsten, is being assembled ready for commissioning and launch.