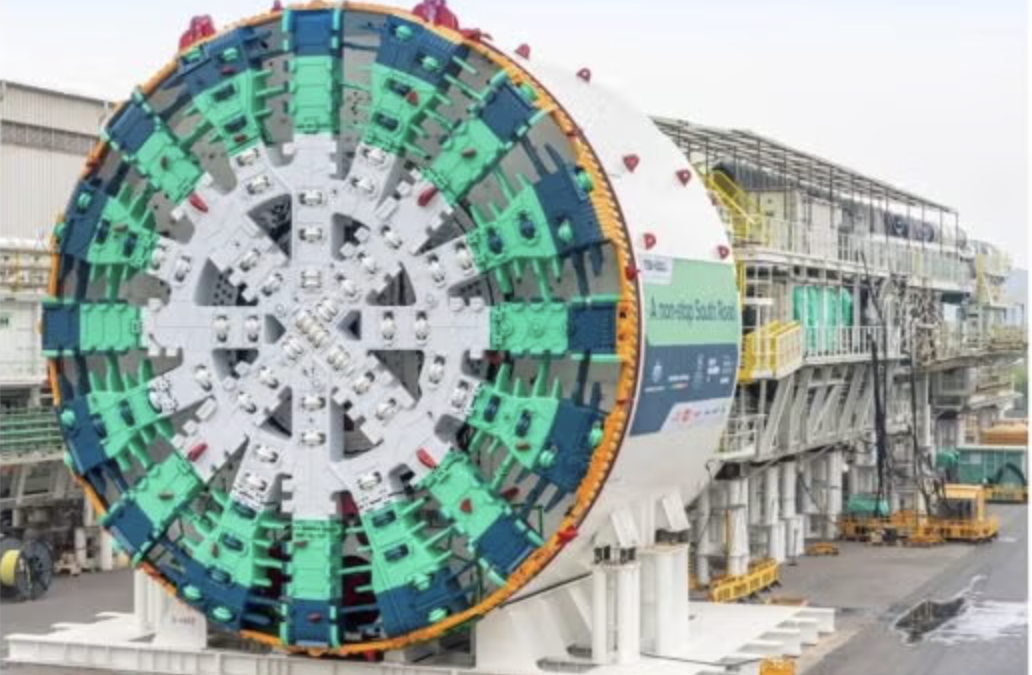

June 9th witnessed “Mawan”, the 15.53m diameter slurry Tunnel Boring Machine manufactured by China Railway Engineering Equipment Group Co. Ltd. (CREG), successfully break through into the reception shaft on the exemplary excavation of Shenzhen’s Mawan Subsea Tunnel project.

The project has a 2063m long tunnel boring machine drive comprising a subsea section of 1100m, which is critical to the total project.

“Mawan” overwhelmed four principal construction challenges during the excavation. The first was the long-distance alignment of complicated ground conditions, containing 50% mixed ground and 34.15% of full-face hard rock, which meant the tunnel boring machine had to excavate through a significant stretch of high-strength rock.

The second issue was the challenging terrain in the subsea section which can cause tunnel boring machine flotation and deviation from the designed route, mixed with the risk of severe cutter wear and the subsequent demand for cutter changes.

The third problem was the considerable overburden, with the tunnel placed at a depth of over 40m beneath the seabed, with a max water pressure of 5 bar and a maxi rock strength of 193MPa. And the fourth was the extensive cross-section with an outer diameter of the segmental ring of more than 15m.

“Mawan” was designed to work under such challenging conditions, with multiple innovative technologies to secure construction progress and safety.

The best monthly advance recorded was 172m in the mixed ground and the best daily advance of 10m. According to CREG, this has set a new record for the daily progress of large-diameter subsea TBM in China.

The Shenzhen Mawan Subsea Tunnel is anticipated to be operational in 2024. Once completed, it will play an essential role in developing the city’s urban development and transport interconnectivity in the Guangdong-Hong Kong-Macao Greater Bay Area.