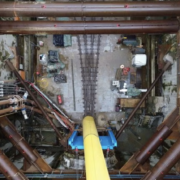

In order to installing GRP pipes for the first time, Bessac Andina has used pipe jacking.

As part of the TransMilenio works on Bogotá’s North Highway, advancing of this project is up to general contractor Mario Alberto Huertas Cotes on behalf of the Urban Development Institute, and involved pipe jacking beneath the busy highway in the Colombian capital.

According to Bessac Andina director Frédéric Sega: “During the operation traffic flows on the highway were uninterrupted.Citizens didn’t even notice that we were installing two large pipes under the freeway”

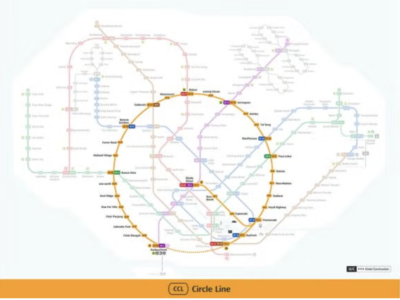

Including the TransMilenio on Highway North, Carrera 9 and a railway line, the project was carried out in two main stages,whereas the first was construction of two launch shafts and two reception shafts to facilitate drilling operations and pipe laying, and then the installation of GRP pipes with diameters from 1000-1200mm using trenchless technology with the pipe jacking micro-tunneling system.

With the aim of decreasing its carbon footprint compared with conventional digging methods, Bessac Andina is adopting trenchless technology. It says pipe jacking is in line with pillar 1 of its environmental roadmap and act now by changing the way we work to integrate the environment into our production processes.

Reducing the excavation of materials, preservation of existing infrastructure, as well as reduced noise and dust emissions, are the advantages of pipe jacking.