Herrenknecht has declared that the contractors working on the Deep Tunnel Sewerage System (DTSS) project in Singapore have finished tunneling works for the second construction phase utilizing a Herrenknecht Vertical Shaft Sinking Machine (VSM).

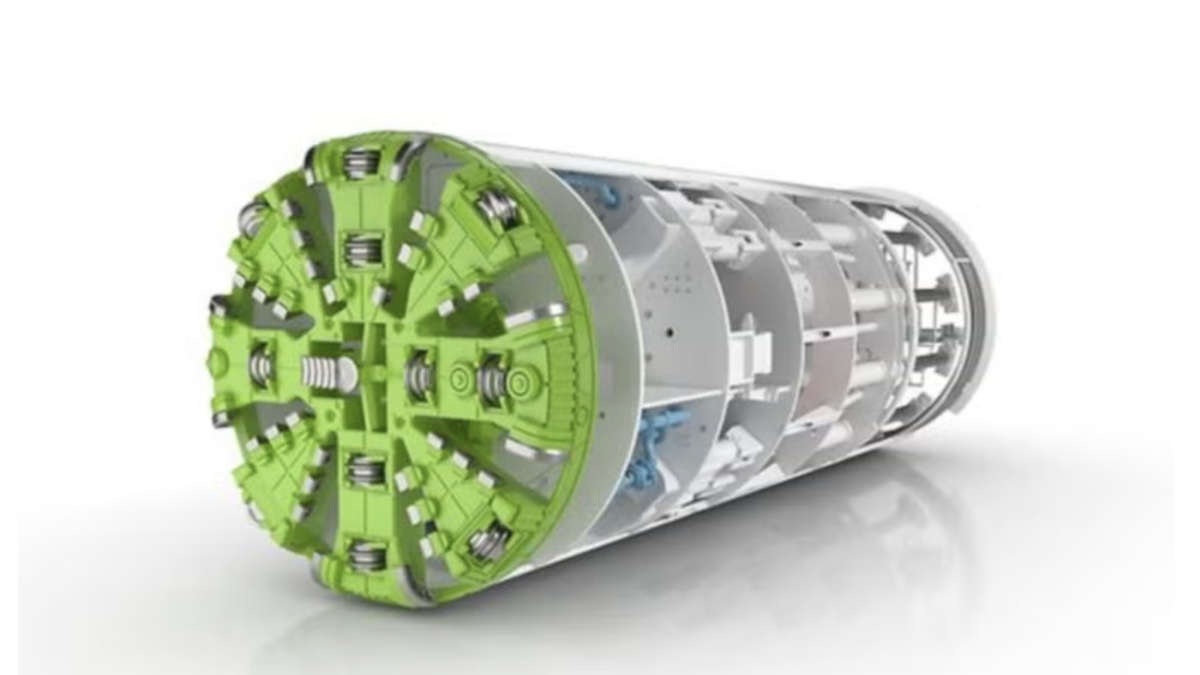

In the second phase of the project, eighteen Herrenknecht Mixshields and one EPB Shield (Earth Pressure Balance Shield), with diameters between 4.50 and 7.56 meters, were selected to excavate the sewage collectors and lined them with segments.

In addition, Herrenknecht supplied 12 separation plants for the Mixshield drives and delivered support services throughout the complete the Deep Tunnel Sewerage System project, which contained remote access to individual machines, allowing them to be monitored and controlled remotely.

During the project, the teams encountered challenges with the ground’s complex geology. The ‘Jurong Formation’ includes sandstone, siltstone, mudstone, limestone, dolomite, and conglomerate. These rock types have been folded considerably due to tectonic plate movements. Accordingly, diverse rock types with different weathering grades usually alternate along a tunnel alignment and even in the cross-section of a tunnel.

Dirk Schrader, Herrenknecht’s general manager of Asia Pacific, stated: “In close cooperation with the customers, we adapted the design of the TBM to the complex geological conditions.”

Moreover, specific solutions were needed for five of the 24 shafts construction in Tunnel Contract T-11 with diameters between 10 and 12 meters. Herrenknecht claims that, in this particular section, with depths of up to 60 meters, there was high water pressure the shafts repeatedly had to resist.

Schrader also noted: “For this reason, for the first time in the Asia-Pacific region, a Vertical Shaft Sinking Machine (VSM) from Herrenknecht was used for sinking the shafts.”