Hydro One’s Celtic Tiger Tunnel Boring Machine (TBM) was lately lowered into the ground after years of designing and planning. It launched construction on a new underground tunnel that is anticipated to deliver a reliable electricity supply in downtown Toronto.

While construction activity on the $120 million infrastructure renewal project started in 2022, early engineering work began in 2018, and the environmental assessment was finished in 2020.

Andrew Spencer, vice-president transmission and stations with Hydro One stated: “This project has been in planning for over three years.”

Spencer added: “We’ve undertaken an extensive process…and through that we worked with environmental consultants, engineers, engaging with the community, business owners, residents, municipal staff to get their advice and input.

“So far everything is trending well from a cost and schedule perspective.”

Hydro One is working with Toronto Hydro and the City of Toronto to coordinate construction requirements and the use of the TBM, plus to underrate disruptions to residents and businesses.

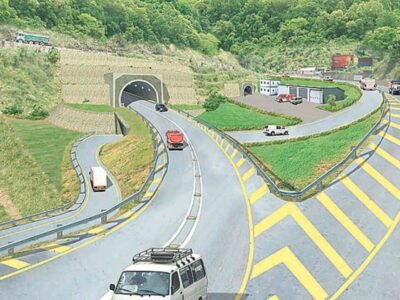

The new tunnel will be approximately 2.5 kilometers long, is located 85 feet under the ground, and will house new high-voltage electrical cables to substitute older ones.

Andrew Spencer expressed: “The depth is based on geotechnical and hydro geological studies that were conducted as part of the early engineering works.”

He continued: “Underneath the downtown core is a myriad of infrastructure: electrical, telecom, water, existing and future. Some of the co-ordination on this was considering future transit projects in the area. We had to co-ordinate with Metrolinx as some of these crosses future locations for the Ontario Line.”

The excavation is said to be finished by early 2024, and the installation of the new cables is predicted to be completed by 2026. Hydro One declares that the project will supply energy to “Hospital Row,” city hall and the financial district. It will operate between Esplanade TS and Terauley TS, which goes from The Esplanade and Lower Sherbourne Street to Bay and Dundas streets.

“This project is replacing existing transmission infrastructure that was installed 70 years ago,” Spencer argued.

Part of the EA process comprised considering alternatives.

Andrew Spencer declared: “There were multiple ways we could have constructed this project.”

“We could have chosen what is commonly referred to as an open cut, when you would either cut in the roadway or the road allowance, like on the sidewalks and boulevards through the city. We would have been able to just excavate down six, eight, 10 feet…install all these cables, backfill it and then repave the road, refinish the sidewalks etc. The downside of doing that is it’s extremely invasive to traffic, residents and businesses,” Spencer continued.

Using the tunnelling method versus the open cut method does cost a little more but minimizes the impact on the city.

He claimed: “It’s also going to be a bit more resilient in the future, a bit more maintainable.”

“This is generally highly reliable infrastructure. In the event that it does need some attention over its typical 50-year-plus life, having it in the tunnel allows us much easier access for our maintenance crews to conduct any inspections or repairs.”

One of the first construction activities undertaken was constructing the entry and exit shafts for the TBM at both ends of the tunnel.

Spencer pointed out: “The crane actually lowering the boring machine down into those shafts, that was an extensive piece of construction.”

He also mentioned: “Each end had to be excavated, shored up as it was being built and all the dewatering activities that go with the standard excavation work had to be undertaken. That work was completed in 2022…in preparation for the launch of the TBM.”

The tunnel boring itself is anticipated to take about a year. The TBM moves nearly 40 to 50 feet a day, depending on the soil conditions, and runs 12 hours a day from 7 a.m. to 7 p.m.

Moreover, Spencer added: “Then we do all the forming that will ultimately be backfilled with concrete and will form the liner of the tunnel.”

He stated: “We’re drilling at 12-foot diameter hole and by the time you put the concrete lining around that tunnel, it’s going to shrink into a 10-foot-diameter so the finished concrete walls are about a foot thick on either side.”

After that the installation of drainage systems and electrical cables starts.

Andrew also claimed: “These cables are probably about five-to-six-inch diameter.”

“Those get installed throughout the tunnel. They get attached to the walls so they are safe and secure and maintainable in the future and then we install…lighting systems, ventilation systems. Because this is underground, we need to make sure there is a supply of fresh air for any future maintenance or inspection purposes,” Spencer said.