With the signing of the work completion report, all the primary works have been completed at the construction site of lot H71 – “Eisack River underpass” of BBT (the Brenner Base Tunnel).

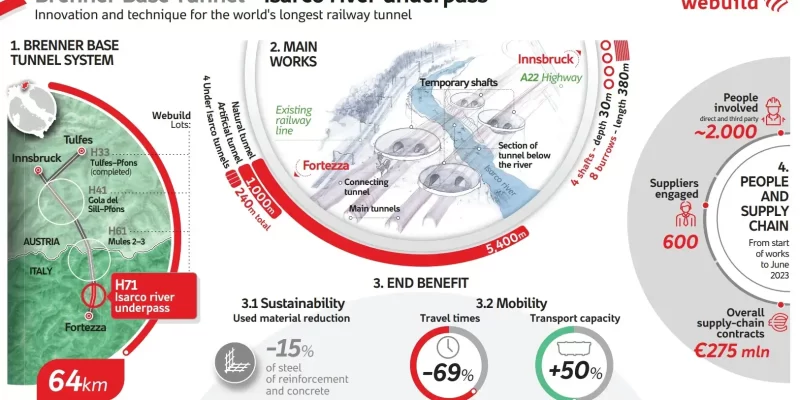

A consortium of firms led by Webuild, comprising Strabag, Collini Lavori, and Consorzio Integra, with a supply chain of 600 companies involved, is engaged in building the works.

The lot contains an underpass of the Eisack River which will contribute to the completion of the Brenner Base Tunnel, which is among the most strategic sustainable mobility projects that Italy is investing in.

After the construction work completion for the future railway tunnels, the site will be cleared, and the areas will be greened in a manner consistent with the seasonality of the tree species.

The Brenner Base Tunnel is a record-breaking tunnel linking Fortezza, Italy, to Innsbruck, Austria. With a total length of 55 kilometers (64 kilometers if the current Innsbruck railway bypass is included), it will be the most extended underground railway connection worldwide. It will link Italy to Austria across the Alps, enabling a considerable reduction in travel time.

Presently, traveling from Fortezza to Innsbruck by train takes 80 minutes for passenger traffic and 105 minutes for freight traffic, however, when the tunnel is operational, it will take only 25 and 35 minutes, respectively.

The Eisack Underpass lot includes the southernmost part of the Brenner Base Tunnel, before the access to the Fortezza station. The lot has concerned the boring of around 6 kilometers of tunnels operating for a total of 240 meters beneath the bed of the Eisack River. It is worth mentioning that advanced and innovative technology was used in its construction.

For the Eisack River underpass, one of the most complicated sections, the technique of ground consolidation by freezing was applied, enabling the tunnels’ construction where there is a strong existence of groundwater and in complete respect of the environment, preserving flora and fauna.

The freezing technique, which comes before the excavation phase, secures the freezing of a portion of the soil between the tunnel to be bored and the river above, adequate to make the excavation impermeable to water and secure stability. Its application forms a pre-consolidation phase, in which the soil is drilled into the section below the river, and its permeability is decreased by cement injections.

Next, there is the freezing phase with the introduction of liquid nitrogen at a temperature of about 196 degrees Celsius below zero: the cooling liquid circulates in the holes made near the excavation perimeter to produce a one-meter-thick shell. The last stage is when the ice shell is maintained by the brine usage brought to a temperature between 30°C and 35°C below zero.

The Brenner Base Tunnel is an essential part of the Scandinavian-Mediterranean Corridor, a fundamental component of the TEN-T trans-European transport network, which lies on the Munich-Verona axis, where Webuild is now working on five projects, as well as one already finished.

On the Italian side, plus the Eisack Underpass lot, the Mules 2-3 lot is being built with the Ghella Group. It is undertaking work on the Sill-Pfons Gorge lot on the Austrian side and has already finished the Tulfes-Pfons lot.

In addition to these lots, there are works for the Fortezza-Ponte Gardena high-capacity line and the Trento railway bypass for linking the line to Fortezza and Trento, respectively.