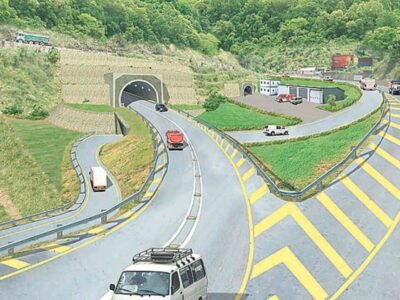

Excavation of a second tunnel at Lobs Hole for Australia’s Snowy 2.0 pumped-hydro project, has been completed by Future Generation JV.

Following completion of tunneling the adjacent main access tunnel (MAT) in October 2022, using TBM Kirsten, boring of this tunnel which is a 2.93km long emergency, cable and ventilation tunnel (ECVT) has been done and fully lined with 13,140 concrete segments.

According to Snowy Hydro CEO Dennis Barnes: “Snowy 2.0 was continuing to make solid progress, with around 6km of tunneling by TBMs completed, and drill and blast excavation of the power station cavern about to start.”

He also added: “We are extremely pleased the ECVT excavation has been completed and the whole project team is excited to be moving into the next critical phase of construction. Our huge power station cavern will be located about 800m underground and will be one of the largest and deepest in the world. We are also using drill and blast methods to construct cross passages linking the ECVT with the MAT.”

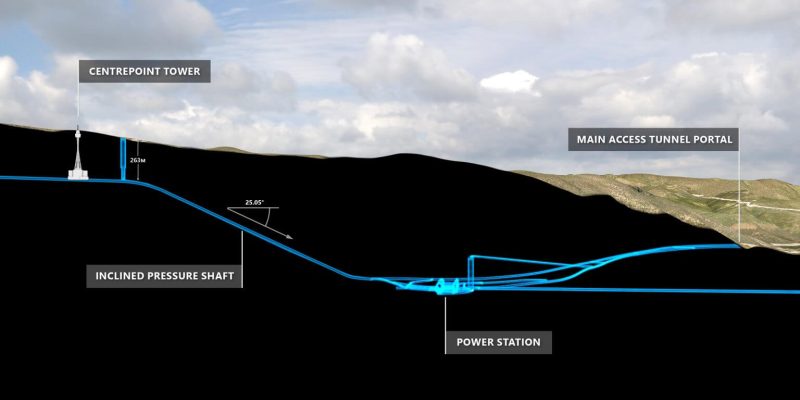

In order to excavating the inclined pressure shaft and line it with concrete segments, TBM Kirsten is currently being modified.

“The shaft is 1.45km long and excavating a segment-lined tunnel of this length at a very steep 47% incline using an 11m diameter TBM is without precedent internationally,” said Barnes.

Changing the levels of the TBM’s tanks as well as mechanical equipment, are the modifications to be applied to Kirsten, hence they remain horizontal when travelling up the incline, and converting the walkways into steps and ladderways.

Additionally, in order to extracting excavated rock from the cutterhead to a sandwich conveyor system with face-to-face rubber belts that help constrain the crushed rock so it can be transported down the slope without spillage, a screw conveyor is being installed.

Additional plant and equipment will also be installed in the ECVT tunnel to support the excavation activities including: an overhead crane, a conveyor transfer station, monorail manrider for personnel access, and rack and pinion mechanism for plant access to the TBM.

Although the number of current workforce in this project is over than 2,700 across four major worksites building Snowy 2.0, the project is not without its problems.

As Barnes said due to the result of four factors, which are: the soft ground that halted tunneling at Tantangara; some technically complex design elements requiring more time to complete, making the final design now more expensive to construct; the Covid-19 pandemic; and the effect of global supply chain disruption and inflation impacting the cost and availability of a skilled workforce, materials, and shipping, it was announced completion of the project may be postponed by up to two years.

In December last year, TBM Florence stopped work on the headrace tunnel at Tantangara after a surface depression developed above the machine. The TBM was transitioning from soft material into harder rock at the time. The New South Wales government has said tunneling cannot resume until Snowy Hydro has demonstrated the project can proceed without further environmental damage.