With the project’s TBM reaching Greenwich, work on TfL’s (Transport for London) Silvertown Tunnel in east London has achieved another milestone.

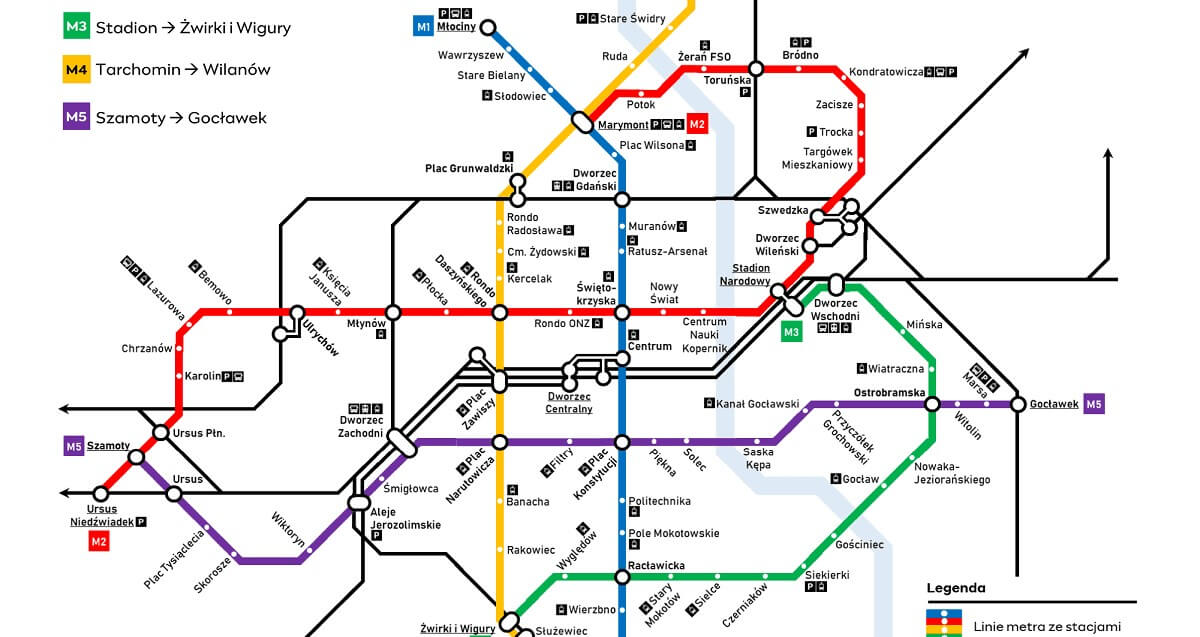

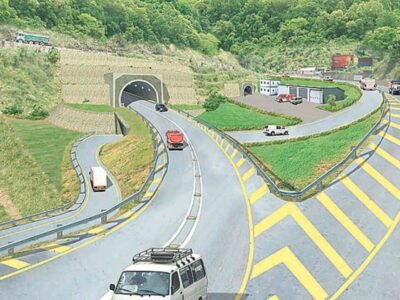

The new 1.4km road connection contains 1.1km long twin bored tunnels and will link Silvertown on the north side of the Thames with the Greenwich peninsula on the south side. The sections of the tunnel not being excavated by the tunnel boring machine will be formed by cutting and covering tunnels and retaining walls as the access ramp gets to the ground level.

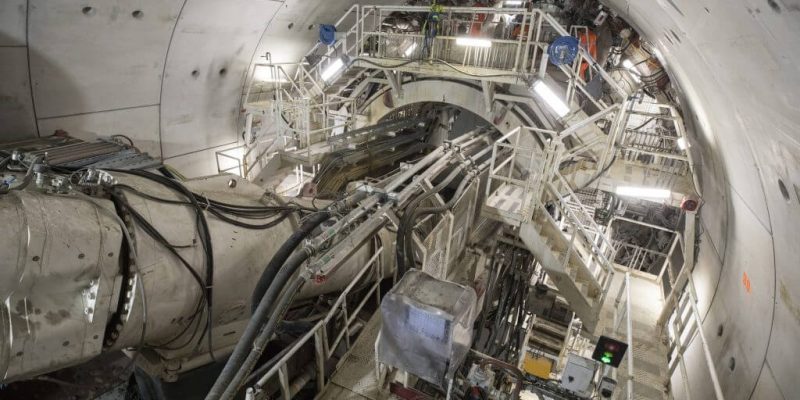

The tunnel boring machine is named Jill and is driving the project’s first 1.1km long bore. Since its launch in August, the Jill has journeyed about 900m and now has just a short way to go before it arrives at the rotation chamber. Once reached, the main contractor, Riverlinx – a JV comprised of Ferrovial, Bam Nuttall and SK ecoplant – will work to rotate the machine and send it back on the return travel under the river to the Silvertown site.

Not only is Riverlinx using the United Kingdom’s largest diameter tunnel boring machine at 11.87m, but it will also be turning the 1,200t TBM around in the shaft at Greenwich with just 30mm clearance before it tunnels back to Silvertown.

Moreover, the contractor will use ground freezing techniques to stabilize the ground before mechanically tunnelling the cross passages. This is a rarely used method in the UK as a scheduled approach and one more commonly associated with emergency work.

The latest landmark comes after a conveyor fire on 27 September held tunnelling work for ten days when the tunnel boring machine had hardly bored 40m.

The investigation done by a forensic specialist into the incident has now resulted in an industry-wide safety notice being administered by Riverlinx, as there are worries that the trigger for the fire is a risk to other tunnelling projects as well.

Analysis of the fire and CCTV represented that hot works earlier in the day, which ended at 5.30 pm, caused smoldering within the hopper chute lining, causing it to ignite at 10.20 pm, despite being a wet day. The tunnel boring machine and conveyor were not operating between the completion of the hot works and the fire breaking out.

The consequential fire caused damage to the high-angle conveyor used to clear spoil from the tunnel. However, Riverlinx project manager, Ivor Thomas, claimed that the organization’s evacuation policy worked right as planned and no one got hurt during the incident.

Before the fire incident, getting work on-site started had not been straightforward, with local stakeholders conveying concerns that traffic from the operational tunnel is said to worsen air quality rather than improve it.

However, the priority of Riverlinx is now on the construction program. It should meet TfL’s 2025 target opening date, and under the contract’s terms, TfL will only begin to pay Riverlinx for its work when the tunnel is operational. When NCE asked Thomas about the main challenges, he stated: “The program is brutal, we have a big machine and constrained sites,”

“Rotating the TBM is also complex and some of the cross passages are located in some tricky ground.”

On the tunnel boring machine’s journey under the Thames, it passes via the London Clay, the water-bearing Harwich Formation and the Lambeth Group, which can also contain water. This has produced the need for ground freezing during cross-passage construction. The alignment only prevents passing into the Chalk.

Alessio Menghini, Riverlinx TBM manager, said he is envisioning water pressures of up to 3.2 bar during the drive, thus, Riverlinx decided to use an earth pressure balance tunnel boring machine for the work because of the ground conditions.

However, the contractor adapted the vertical alignment of the excavation to give a little more coverage as the machine passes below the Thames. The original design had 6.5m of cover, but that has now changed to 8m.

A breakthrough into the rotation shaft at North Greenwich is assumed at the end of January, and it is expected that it will take four months to turn the TBM about ready for re-launch to drive the second excavation.

Currently, Riverlinx envisions the second tunnel drive to be finished by the end of 2023, and TfL is now choosing 2025 as the opening date for the new road tunnel.