Due to escape of bubbling foam at ground level through a pre-existing borehole, tunneling process in Ruislip for High Speed 2 (HS2) halted for two hours on Saturday 18 February.

Although the investigations are undergoing, Skanska Costain Strabag joint venture’s (SCS JV) work has resumed after pausing as a safety precaution.

According to a HS2 spokesperson: “Upon discovering the small pool of foam in Ruislip, HS2’s main works’ contractor SCS JV sealed off the area to investigate. The pool appears to have come out of a pre-existing borehole, causing foam to travel up and pool on the surface. The area is safe, the leak has been sealed, and the foam has been cleared. There has been no impact on the program schedule.”

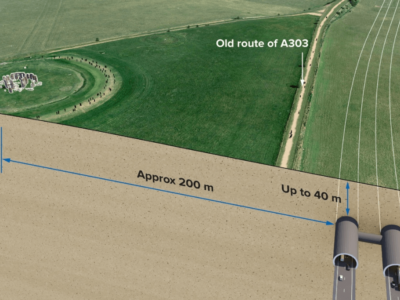

Using two Tunnel Boring Machines (TBMs), the construction process of more than 20km of twin-bore tunnels on the HS2 route to its southern terminus at Euston is now undergoing by SCS JV. In October 2022, these TBMs were commissioned for the 8km long tunnels from West Ruislip to Greenford.

While initially the Ruislip Rugby Football Club reported the incident as the foam was placed within its property, HS2 stated the club was not impacted as the borehole sits far away from the pitch and close to the land boundary.

In order to drying the leak, the TBM was paused for around two hours between 2pm and 4pm on Saturday. Also as HS2 claimed, currently the borehole is sealed behind one of HS2’s TBM tunnel rings.

“It will continue to monitor the area over the next few days and install additional ground anchors to ensure there is no subsidence,” said SCS JV.

In accordance with tunneling specialist Bill Grose’s believe, the decision of halting the TBM while investigating and then stabilizing the situation before carrying on the tunneling, is a right action from HS2.

He continued: “The reports so far don’t say whether it is an HS2 borehole or someone else’s. Assuming it’s the former, I imagine that there will be some questions asked within HS2. Boreholes are usually positioned some distance horizontally from the tunnel alignment and are grouted on completion to prevent this type of occurrence and of course would be recorded on a GIS or BIM model for the tunnellers to be aware of.”

“The TBM will be injecting drilling fluid, the foam, at the tunnel face to keep the face stable and to help remove spoil. The drilling fluid will be under pressure and will therefore exploit any flow route, such as a fissure or other void at a lower pressure. The borehole, if not fully sealed would provide a route to ground level for the pressurized drilling fluid,” added Bill Grose.