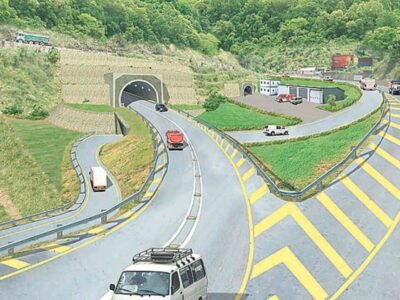

Tunneling technology has taken giant steps forward in the last 50 years to deliver evermore intricate and larger projects, but what challenges must the sector address over the next 50 years?

With the opening of the Kingsway Tunnel under the River Mersey and the completion of the London Underground’s Victoria Line in the early 1970s, the foundation of the British Tunnelling Society took place. In 1972, the first subject of NCE was published, and over the last half-century has charted much progress in the tunneling sector.

Today’s tunneling industry leading figures joined along with NCE and Vinci Construction Grands Projects to contemplate the safety, diversity, and technological advances of the past 50 years – and went ahead to the 2070s – in a wide-ranging debate.

Bill Gros, the independent consultant who began working as a civil engineer for London Underground 50 years ago, before spending 35 years working for Arup, stated that health, safety and wellbeing performance has “moved on immeasurably” in the last five decades.

However, Mott MacDonald’s principal tunnel engineer, David Naylor, called up a sad note, pointed to a memorial on the Kingsway Tunnel for the lives of nine men who died during its construction.

Rosa Diez, a colleague of Gros and Mott MacDonald’s project director, referred to another area where the tunneling sector has progressed since the 1970s. “As a woman, it was considered to be dangerous or forbidden in many countries to [work in] a tunnel 50 years ago,” Diez evoked.

Meantime, Vinci Construction Grands Projects UK managing director, François Pogu, expressed that the tunneling sector’s technical capability has improved too.

He said: “The size of the tunnel boring machines (TBMs) is getting bigger and bigger; we’re going deeper and longer; we’re less limited in a very specific geology.”

Cowi UK’s managing director, Andy Sloan, mentioned that a recognized tunneling sector within the construction industry nowadays lives is itself an attainment to be proud of. He said: “That we’ve coalesced around the identity of being underground professionals is the biggest change I’ve seen.”

Patrick Lane-Nott, a former Formula One system analyst and HyperTunnel’s engineering director, admitted the safety advancements that have taken place in the tunneling sector but says the magnificent use of technology will also remove the risk to humans and decrease costs.

Milestone Projects

Pogu was met with agreement when he mentioned the Channel Tunnel, which opened in 1994, as one of the construction industry’s most remarkable triumphs of the past five decades. More recently, the much-maligned Crossrail project won plaudits for its technical work in London’s overcrowded underground space.

Diez indicates the significance of learning from the industry’s mistakes plus its successes: “Heathrow Express was the last major collapse that we had in the UK and it triggered quite a lot of health and safety reviews and reconsideration of construction with sprayed concrete lining.”

Grose agreed and continued: “Sprayed concrete lining is now the go-to technique for station excavation and cross passages and that wouldn’t have happened as quickly if Heathrow Express hadn’t collapsed.”

Moreover, he mentioned the Victoria line, which was completed in the early 1970s, referring to its pioneering use of a rotary shield and precast concrete: “Those two things were massive innovations, massive steps forward.”

Nevertheless, Lane-Nott believes that tunneling’s game-changing innovation is still upcoming: “In the aviation industry they went from piston engines to the jet engine; in the automotive world, battery technology is making the electric car viable – I don’t see that happening in tunneling.”

Sloan declared that innovation in construction is stymied by the amount of focus on community engagement and planning: “It took six years to submit the development consent order application for the Lower Thames Crossing, which shows just how the tunneling element is actually quite small in terms of the effort that’s required.”

He added: “It is almost an afterthought that we’re going to build a tunnel.”

Naylor stated that automated segment placing trials are in progress on National Grid’s London Power Tunnels Phase 2 project, and asked: “If we have this same conversation in 50 years’ time, how many people are actually going to be on a TBM?”

Future challenges

Climate change and the drive to carbon net zero are the challenges that the tunnelling sector should manage way before the next 50 years are up. Pogu pointed out that a lot of low-carbon innovation is underway, but it calls for standards and regulations to force the industry to move forward.

Sloan warned and said that although the tunnelling industry is making gradual progress towards net zero, it “will not get there unless we do something radical”.

He said if we want to get the cost of projects down, the timing of getting from an idea to a spade in the ground has to enhance over the next 50 years.

Pogu asked: “How do we decarbonize a whole project?”

He continued: “I don’t think you can without allying renewable green energy with infrastructure,”

“Until we embrace green fuels, renewable energy in the production of TBMs and in the production of concrete, we will get nowhere near carbon neutrality.”

Lane-Nott mentioned that a lot of tunnelling machinery is only used once. As a result, it racks up a high embodied carbon score. However, he added that tunnels should be judged against the alternative solution.

“A tunnel in the right circumstances and built in the right way can be way more efficient and greener than just looking at the material content alone,” Lane-Nott pointed.

Demand for skills

As the discussion pivoted toward future skills, Grose asked whether geological knowledge is going to matter in the future.

Grose expressed: “We are developing technology to effectively de-skill the industry,”

“The skills are going to be needed to build the TBM that doesn’t care what the geology is.”

However, Sloan expressed that he is dubious about the emergence of “ground-agnostic tunnelling”.

He insisted: “There will always be a need to understand the ground because it’s so varied,” He added: “I think there needs to be changed in the way we attract young talent into engineering and other sciences.”

Diez demanded for an “evolution of training and university degrees so that they are more technologically geared and not so technical”, claiming that traditional engineering degrees are not exciting anymore.

Naylor argued that procurement requires an overhaul before 2072: “The timing of getting from an idea to a spade in the ground has to improve over the next 50 years if we want to get the cost of projects down.”

In addition, Sloan pointed out that robots replacing people working underground “has to be the direction of travel.”

This report is based on a round table discussion held in November 2022. The discussion was held in association with Vinci Construction Grands Projects.

Contributing to the discussion were:

Rosa Diez project director, Mott MacDonald

Bill Grose independent consultant

Patrick Lane-Nott director of engineering, HyperTunnel

David Naylor principal tunnel engineer, Mott MacDonald

Francois Pogu UK managing director, Vinci Construction Grands Projects

Andy Sloan managing director, Cowi UK

Claire Smith editor, NCE